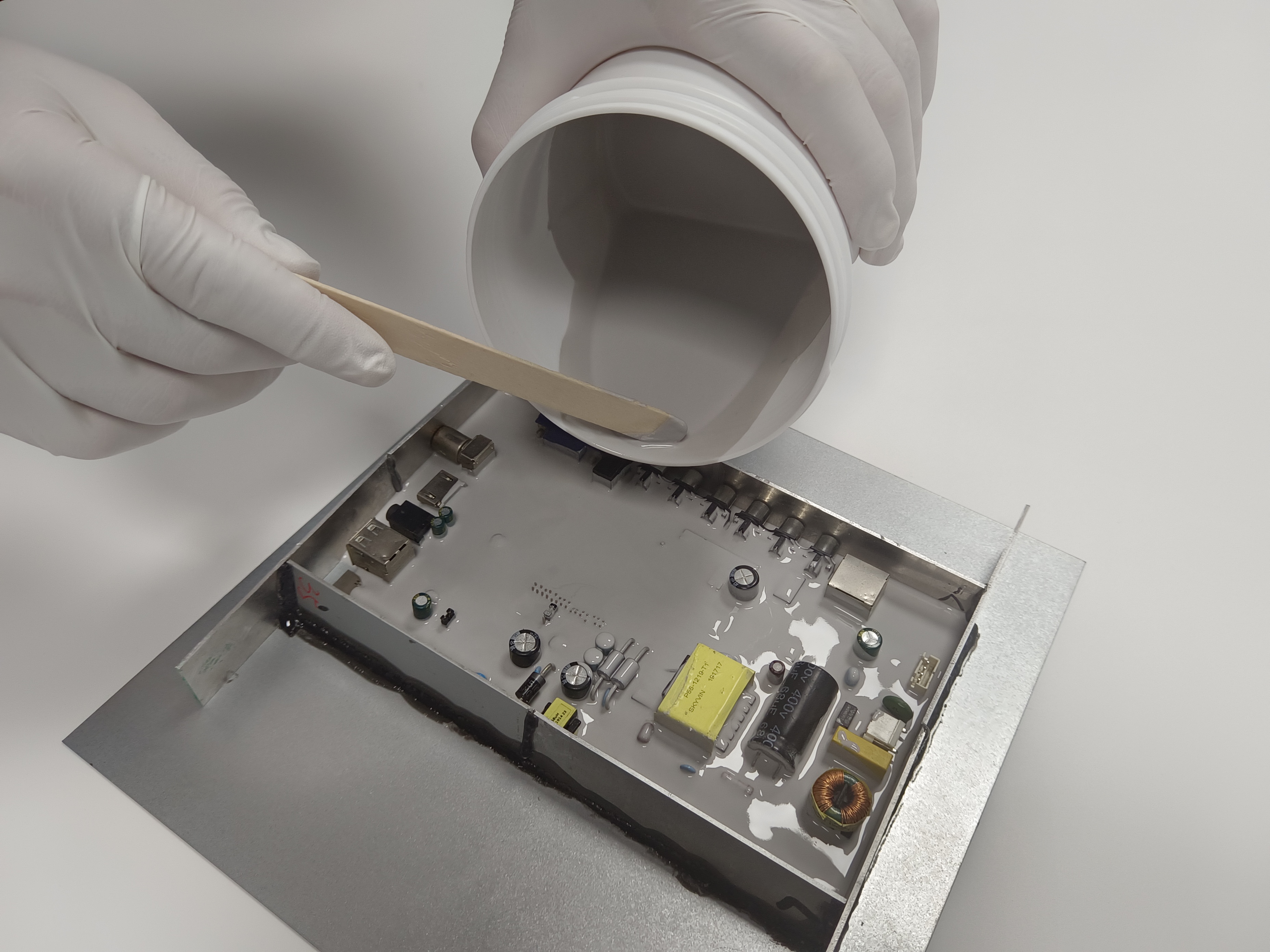

Thermal conductive Silicone Potting Compound for The Electronic and Electrical Industry

Time: 2024-12-30 14:12:49 Copyfrom: SuZhou Volsun Electronics Technology Co.,Ltd.

With the rapid development of the electronics industry, electronic products are becoming more and more sophisticated and miniaturized, and the requirements for potting materials are getting higher and higher. Thermal conductive silicone potting compound has gradually become the preferred potting material in the electronics industry due to its excellent performance.

About silicone potting compound products

Thermal conductive silicone potting compound is an elastomer with silicone rubber as the base material, fillers, cross-linking agents, catalysts and other additives added, and a three-dimensional network structure formed by chemical reaction. It has good adhesion, temperature resistance, weather resistance, electrical insulation and waterproof and moisture-proof properties, and is widely used in electronic components, LED lighting, power equipment and other fields.

Performance characteristics of silicone potting compound

Excellent electrical insulation: Silicone potting compoud has a high resistivity, which can effectively isolate electronic components from external electric field interference, ensuring the stable operation of electronic products in complex environments.

Good temperature resistance: Silicone potting compound can withstand a temperature range of -60℃ to 200℃, adapt to various harsh environments, and ensure the normal operation of electronic products under high or low temperature conditions.

Excellent bonding performance: Silicone potting compound has good bonding properties to a variety of materials, such as metal, ceramic, glass, plastic, etc., which is beneficial to improve the structural strength of electronic products.

Weather resistance: Silicone potting compound has excellent resistance to ultraviolet rays, ozone, high and low temperature alternation, etc., which can ensure the long-term use of electronic products outdoors.

Waterproof and moisture-proof: Silicone potting compound has excellent waterproof and moisture-proof properties, which can effectively prevent short circuits, corrosion and other problems caused by moisture in electronic products.

Easy to operate: Silicone potting compound has good fluidity and self-leveling properties, which is convenient for construction and improves production efficiency.

Application fields and advantages of silicone potting compound

1. Electronic components: such as transformers, relays, controllers, sensors, etc., can improve the product's anti-seismic, moisture-proof and insulation properties after using potting compound.

2. LED lighting: Silicone potting compound can protect LED chips and improve the heat dissipation performance and light efficiency of lamps.

3. Power equipment: such as cable connectors, switches, sockets, etc., can improve the product's waterproof, moisture-proof and insulation properties after potting.

4. Automotive electronics: such as automotive sensors, controllers, etc., potting can improve the product's temperature resistance, shock resistance, and waterproof performance.

How to choose silicone potting compound?

According to the actual application scenario and thermal conductivity requirements, select the corresponding thermal conductivity, hardness, viscosity, etc.

Volsun can provide customized services according to customer needs, welcome to contact us!

KEYWORD:Thermal conductivity,Potting compound

RELATED_ARTICLES:

Thermal conductive Silicone Potting Compound for The Electronic and Electrical Industry

Polyurethane Potting Compound for Circuit Control Panel

Volsun VS-TP1501 Thermal Conductive Silicone Potting Compound for Electronic Components

Volsun High Performance Thermal Conductive Gap Filler for Electronics Industry

VS-TP2001 Silicone Thermally Conductive Potting Compound