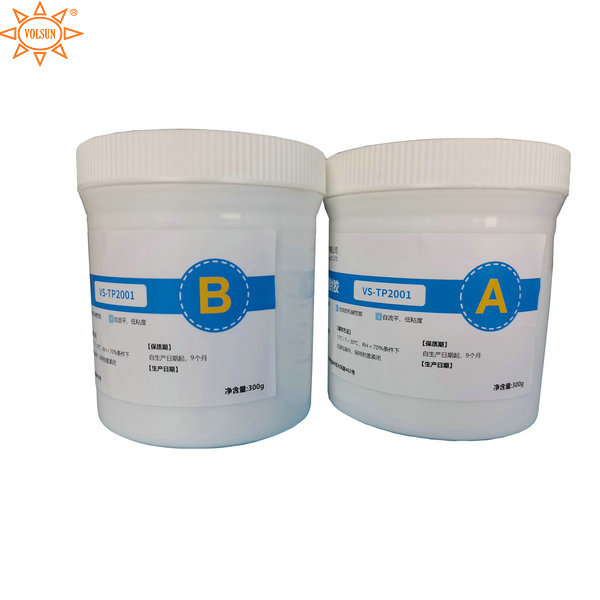

Volsun VS-TP2001 Thermal Conductive Organosilicone Compound Potting

Time: 2023-11-11 14:15:33 Copyfrom: SuZhou Volsun Electronics Technology Co.,Ltd.

Description

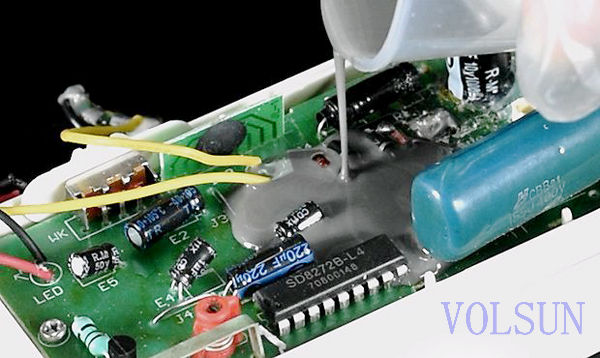

VS-TP2001 is a two-component 1:1 heat-curing silicone heat-conductive potting adhesive, which cures at room temperature or after heating to form elastic heat-conductive silicone rubber. It is specially designed for the manufacture of electronic and electrical products and modules, such as the potting protection of high-power power supply modules, frequency converters, sensors, etc., and the connection and fixation between on-board electronic devices and PCBs.

Features

Operating temperature: -70℃~+200℃

Excellent mechanical properties and ductility

Excellent thermal conductivity and aging resistance

Low viscosity, self-leveling, excellent seam drilling ability

Low modulus, low stress, good adhesion to metals and plastics

Technical Performance

|

Item |

典型值 Typical value |

测试方法 Test method |

|

Mixing ratio |

1:1 |

/ |

|

Color(After mixing) |

Grey |

|

|

Viscosity(Component A) @25℃ |

5500±500cps |

ASTM D2196 |

|

Viscosity(Component B) @25℃ |

5500±500cps |

ASTM D2196 |

|

Viscosity(After mixing) @25℃ |

5500±500cps |

ASTM D2196 |

|

Opening hours@25℃ |

≥90min |

/ |

|

Curing condition |

30min/50℃;20min/100℃ |

/ |

|

Thermal conductivity |

2.0±0.2 W/m·k |

ASTM D5470 |

|

Thermal resistance |

0.000815m2·k/W |

ASTM D5470 |

|

hardness |

25±5 Shore A |

GB/T 531.1-2008 |

|

density |

2.3±0.2 g/cm3 |

GB/T 1033.1-2008 |

|

Tensile strength |

>0.2 MPa |

GB/T 528-2009 |

|

Elongation at break |

>10% |

GB/T 528-2009 |

|

Flame retardant rating |

V-0 |

UL94 |

|

Breakdown strength |

≥10 kV/mm |

GB/T 1695-2005 |

|

Volume resistivity |

≥ 1.0×1014 Ω·cm |

GB/T 1692-2008 |

|

Dielectric constant (1000Hz) |

4.7~5.5 |

GB/T 1693-2007 |

Dimensions

|

|

Packing |

|

VS-TP2001(1kg) |

Component A 0.5kg; Component B 0.5kg |

|

VS-TP2001(20kg) |

Component A 10kg; Component B 10kg |

|

VS-TP2001(40kg) |

Component A 20kg; Component B 20kg |

|

VS-TP2001(80kg) |

Component A 40kg; Component B 40kg |

|

VS-TP2001(100kg) |

Component A 50kg; Component B 50kg |

Instructions

![]()

Stirring A and B components separately

Mixing the well-stirred components A and B at the ratio of 1:1 (either volume ratio/weight ratio can be used)

The mixed compound is poured into the device to be filled and cured (room temperature or heating can be cured).

Cautions![]()

In order to ensure the uniform distribution of fillers, component A and component B must be separately stirred before mixing, so that each compound is evenly mixed

A and B agents will react and cure each other after mixing, so they need to be used after mixing, and can not be used twice after mixing and curing

When pouring into the protective part, there should be no large debris or other pollutants in the protective part to avoid affecting the adhesion of materials and objects

Before the material is fully cured, keep other objects away from the material, which may affect the appearance and protective performance of the material

Keep this product away from the mouth and eyes. If it enters the mouth and eyes accidentally, rinse it with clean water or go to the hospital

For high thermal conductivity, vacuum defoaming is required prior to perfusion

In low temperature environment, the curing time will be extended correspondingly

Storage conditions and shelf life

![]()

Products should be stored in the original packaging, keep the lid closed, avoid contamination (temperature: 15℃ < T < 30℃; Relative humidity: RH < 70%)

The shelf life is 9months from the production date

Welcome to contact us for more details!

KEYWORD:silicone compound potting, thermal conductive

RELATED_ARTICLES:

Volsun Secures Dual Honors at 2026 Propulsion System Conference

PTFE Heat Shrink Tube FAQs

Volsun Silicone Thermal Pads for New Energy Vehicle Electronic Systems

Why A Leading European Cable Manufacturer Choose Volsun Silicone Rubber Heat Shrink Tubing?

Why EPDM Cold Shrink Tubes Are the Perfect Choice for the Power Industry?

Volsun Receives High Praise from Customers at EP Shanghai 2025

Why Choose Fluororubber Heat Shrink Tubing?