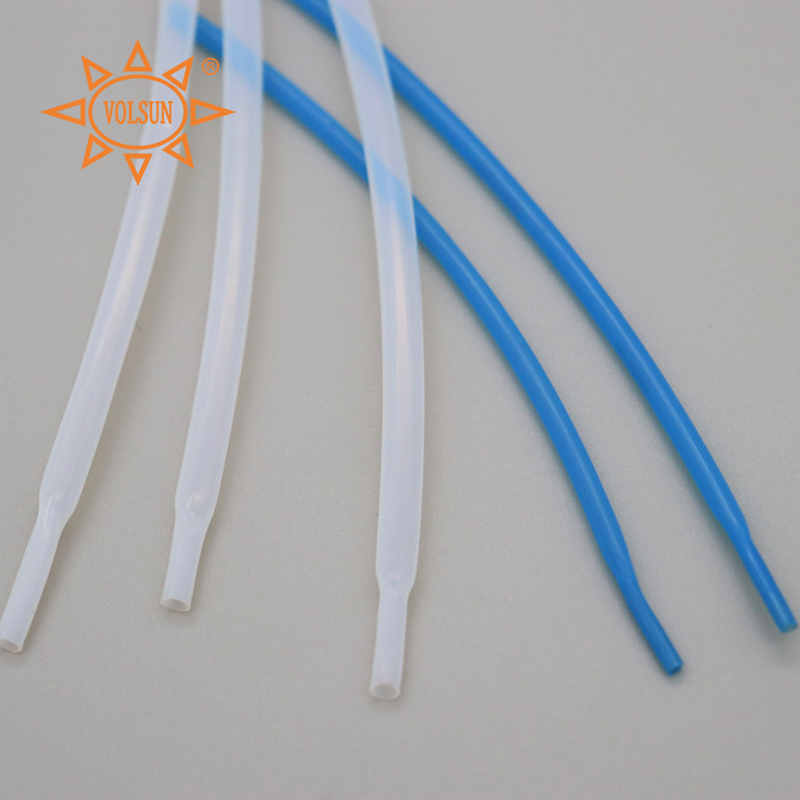

PTFE Heat Shrink Tube FAQs

Time: 2026-01-09 15:54:35 Copyfrom: SuZhou Volsun Electronics Technology Co.,Ltd.

Today, let's discuss some common problems with PTFE heat shrink tubing.

Q1: In what situations do engineers usually specify PTFE heat shrink tubing?

In real projects, PTFE heat shrink tubing is rarely the first material considered, but it often becomes the final decision when operating conditions cannot be fully controlled or predicted.

Engineers typically specify PTFE heat shrink tubing when:

- Operating temperature may exceed 200°C, even intermittently

- Chemical exposure is variable, unknown, or difficult to isolate

- Electrical performance must remain stable over long service periods

- Replacement or maintenance access is limited

In these cases, PTFE is selected not for convenience, but for risk elimination.

Q2: Why is PTFE often chosen when chemical exposure cannot be clearly defined?

From an engineering perspective, material compatibility charts are only reliable when all chemical variables are known.

PTFE heat shrink tubing is frequently chosen when:

- Multiple chemicals are present

- Cleaning agents may change over time

- Occasional exposure to aggressive solvents cannot be ruled out

By using PTFE, engineers avoid redesign cycles and material substitution risks, especially in chemical processing and semiconductor environments.

Q5: What trade-offs should engineers be aware of when selecting PTFE heat shrink tubing?

PTFE heat shrink tubing offers exceptional performance, but it is not a universal replacement for all heat shrink materials.

Typical trade-offs include:

- Higher installation temperature

- Reduced flexibility compared to polyolefin

- Higher material cost

Engineers usually accept these trade-offs when long-term reliability outweighs assembly convenience or short-term cost savings.

Q6: What shrink ratios are commonly used in PTFE heat shrink applications?

In most engineering projects:

2:1 shrink ratio is preferred for controlled, dimension-critical assemblies

4:1 shrink ratio is used for connectors, irregular geometries, or retrofit protection

Higher shrink ratios offer greater tolerance during installation but require more careful heat control to ensure uniform recovery.

Q7: Is PTFE heat shrink tubing suitable for contamination-sensitive environments?

Yes. PTFE is widely selected for environments where material purity and stability are critical.

Typical applications include:

- Semiconductor process equipment

- Cleanroom instrumentation

- High-purity fluid and gas systems

Engineers value PTFE for its low outgassing and minimal extractables, reducing the risk of process contamination.

Q8: How does PTFE heat shrink tubing perform over long service life?

Unlike many polymer-based heat shrink materials, PTFE does not rely on plasticizers or fillers that degrade over time.

In long-term field applications, PTFE heat shrink tubing demonstrates:

- No embrittlement

- No cracking due to thermal cycling

- Stable electrical and mechanical properties

This makes PTFE suitable for 10+ year service life expectations, particularly in aerospace and industrial equipment.

Q9: Can PTFE heat shrink tubing be used in outdoor or UV-exposed installations?

PTFE is inherently resistant to:

- UV radiation

- Ozone

- Weathering

For outdoor installations or equipment exposed to sunlight, PTFE heat shrink tubing provides predictable aging behavior, unlike many standard heat shrink materials that gradually harden or discolor.

Q10: When is PTFE heat shrink tubing considered the “default safe choice”?

In engineering practice, PTFE heat shrink tubing is often considered the safest option when any two of the following conditions apply:

- Operating temperature above 200°C

- Chemical exposure is uncertain or aggressive

- Long-term reliability is critical and maintenance access is limited

In such scenarios, PTFE minimizes downstream risk—even if it is not the lowest-cost or easiest-to-install solution.

KEYWORD:ptfe heat shrink tube

RELATED_ARTICLES:

How to Select the Right EPDM Cold-Shrink Tube Specifications?

The Application of Cold Shrink Tubes In Electric Power Industry

The difference between EPDM rubber and silicone rubber

Features and application of EPDM cold shrink tube

Application case and technical performance of EPDM cold shrink tube

Large size EPDM cold shrink tube for cable jointing protection

Volsun Restart Normal Work on 20th,2,2021

"Manufacturing Excellence & Innovation Awards" by #madeinchina in 2021

Introduction detail of EPDM cold shrink tube and application

Telecommunication cold shrink tube—EPDM rubber cold shrink tube

Volsun Tapered EPDM Cold Shrink Tube

Volsun EPDM cold shrink tube for power industry and other industrial applications