Environment test and IP67 test of cold shrink tube

Time: 2021-10-28 09:42:09 Copyfrom: SuZhou Volsun Electronics Technology Co.,Ltd.

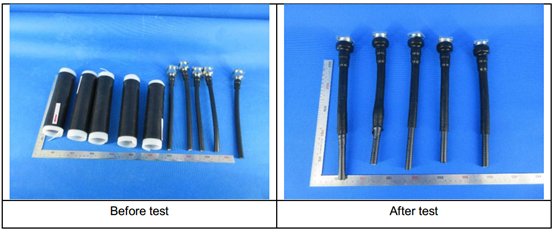

Today we will introduce two test items of silicone cold shrink tube,one is the high and low temperature test,the other is the IP67 waterproof and sealing test.First is the high and low temperature test,the following are the test items and typical test data.

|

Test Item |

Silicone cold shrink tube(Typical Data) |

|

High temperature sealing test(Install the cold shrink tube on the cable,put them in the water by 3min. 70℃/95%,1h ) |

No cracking No water enter into the samples |

|

Low temperature test(-40℃,96h) |

No cracking |

|

High temperature test(70℃,16h) |

No cracking |

|

Low and high temperature test(-40℃,3h/70℃,3h,5 recycles) |

No color change No cracking |

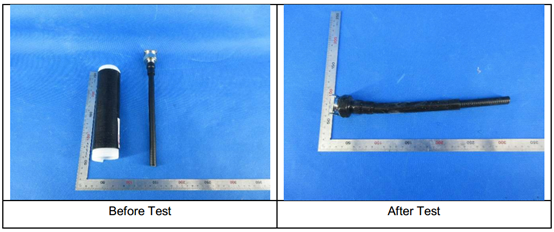

Next we will introduce the IP67 test items here.

1. Test item: IPX7

Test Standard: GB/T 4208-2017

Test condition:

Depth: 1.0 meter

Test Time: 30 min

Labor environment: 15℃-35℃,25%RH-75%RH

Test result: Pass,No visible water at the coonection between cable and sample

2. Test item:IP6X

Test standard: GB/T 4208-2017 and client’s requirement

Test condition:

Test Dust: Talcum powder

Dust Concentration: 2kg/m³ chamber volume and be kept in suspension during the test

Test time: 8 hours

Lab environment: 15℃-35℃,25%RH-75%RH

Test result: Pass,no visilbe dust in the cable and samples connection

KEYWORD:cold shrink tube,silicone cold shrink tube

RELATED_ARTICLES:

How to Select the Right EPDM Cold-Shrink Tube Specifications?

The Application of Cold Shrink Tubes In Electric Power Industry

The difference between EPDM rubber and silicone rubber

Features and application of EPDM cold shrink tube

Application case and technical performance of EPDM cold shrink tube

Large size EPDM cold shrink tube for cable jointing protection

Volsun Restart Normal Work on 20th,2,2021

"Manufacturing Excellence & Innovation Awards" by #madeinchina in 2021

Introduction detail of EPDM cold shrink tube and application

Telecommunication cold shrink tube—EPDM rubber cold shrink tube

Volsun Tapered EPDM Cold Shrink Tube

Volsun EPDM cold shrink tube for power industry and other industrial applications