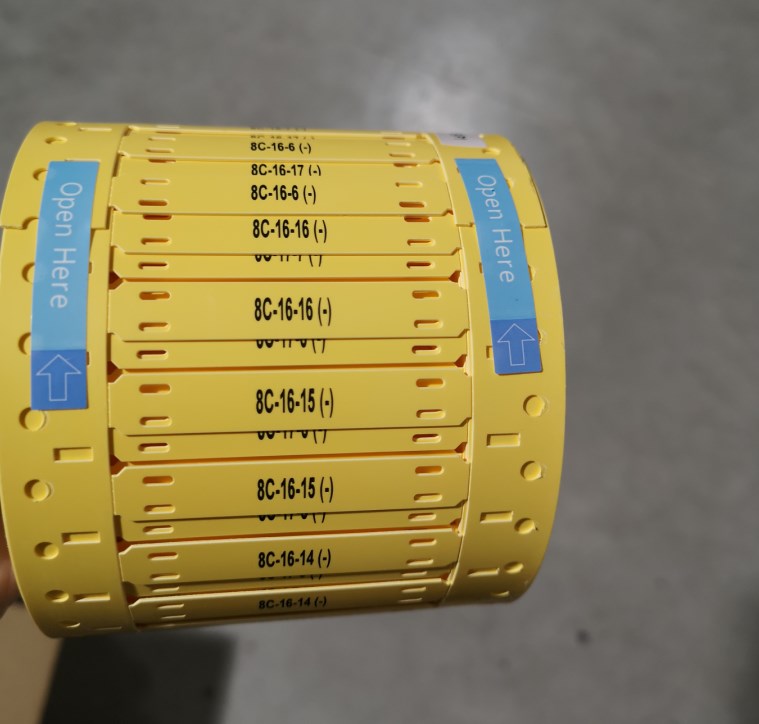

Volsun High Quality Cable Marker Label Cable Identification Tags

- Detailed

Designed for special requirements of cable identification for high-speed rail, subway and urban rail EMU, made of environmentally friendly polyolefin materials. It is bound to cables or harnesses by standard cable ties, and is mainly used to mark the interface and route direction of large-diameter cable harnesses that require high reliability in the locomotive industry. It is especially suitable for the identification of the maintenance cable interface without discharging electrical load to achieve the effect of permanent identification. Meet the requirements of ASTM D 2671B, meet the German DIN 5510, British BS 6853 standard. The physicochemical and electrical properties of the product, such as flame retardancy, smoke density and smoke toxicity index, meet the international locomotive standards. The product printing has excellent abrasion resistance and wear resistance, even if it encounters the erosion of cleaning agents or military fuel, the color code fastness still meets the requirements of the U.S. military standard SAE-AS 81531 and MIL-STD-202F/215J, and maintains the permanent identification effect.

Features

- Halogen-free low-smoke materials are used in the EMU, rail transit, aerospace and naval ship industries, without disconnecting the electrical circuit, to achieve non-stop installation, disassembly and maintenance

- Only using cable, no extra work, easy to operate

- Operating temperature: -55℃ ~ +125℃

- Maximum storage and transportation temperature: +50℃

- RoHS compliant, meets SONY SS-00259

- High temperature non-melting, low temperature non-brittle, scratch resistance, wear resistance, permanent identification

- Computer-printable, any character and logo are easy to design

Technical Performance

|

Specifications |

Typical value |

Test standard |

||

|

Item |

unit |

status |

||

|

Tensile strength |

Mpa |

Before aged |

≥10.3 |

ISO 37 158℃,168h |

|

After aged |

≥6.9 |

|||

|

Elongation at break |

% |

Before aged |

≥200 |

|

|

After aged |

≥100 |

|||

|

Thermal shock |

- |

Before aged |

No cracks, no sticky flow, no dripping |

twine specified shaft diameter,225℃,4h |

|

Withstand voltage |

V |

Before aged |

2500V,No breakdown in 60 seconds |

UL 224 |

|

Breakdown strength |

NV/m |

Before aged |

≥19.7 |

IEC 60243 158℃,168h |

|

After aged |

≥15.8 |

|||

|

Volume resistivity |

Ω.cm |

Before aged |

≥1014 |

IEC 60093 |

|

Water absorption |

% |

Before aged |

≤1.0 |

ASTM D 570 |

|

Bare copper corrosion |

- |

Before aged |

No corrosion |

23℃,Rh 95±5%,24h 175℃,16h |

|

Low bending flexibility |

- |

Before aged |

No cracks |

twine specified shaft diameter,-55℃,1h |

|

Flame retardancy |

- |

Before aged |

S3 |

DIN 5510-2 |

Dimensions

|

Code for order |

Width(mm) |

Length(mm) |

Typing range |

Cable outer diameter range(mm) |

|

|

High (mm) |

Length(mm) |

||||

|

MT-VLD-10.4-45/4- |

10.4 |

45 |

10.4 |

25 |

5.08~12.7 |

|

MT-VLD-10.4-53/4- |

10.4 |

53 |

10.4 |

33 |

5.08~12.7 |

|

MT-VLD-10.4-64/4- |

10.4 |

64 |

10.4 |

44 |

5.08~12.7 |

|

MT-VLD-10.4-76/6- |

10.4 |

76 |

10.4 |

56 |

5.08~12.7 |

|

MT-VLD-10.4-90/6- |

10.4 |

90 |

10.4 |

70 |

5.08~12.7 |

|

MT-VLD-15.0-45/4- |

15.0 |

45 |

15.0 |

25 |

12.7~19.1 |

|

MT-VLD-15.0-53/4- |

15.0 |

53 |

15.0 |

33 |

12.7~19.1 |

|

MT-VLD-15.0-64/4- |

15.0 |

64 |

15.0 |

44 |

12.7~19.1 |

|

MT-VLD-15.0-76/6- |

15.0 |

76 |

15.0 |

56 |

12.7~19.1 |

|

MT-VLD-15.0-90/6- |

15.0 |

90 |

15.0 |

70 |

12.7~19.1 |

|

MT-VLD-20.3-45/4- |

20.3 |

45 |

20.3 |

25 |

19.1~25.4 |

|

MT-VLD-20.3-53/4- |

20.3 |

53 |

20.3 |

33 |

19.1~25.4 |

|

MT-VLD-20.3-64/4- |

20.3 |

64 |

20.3 |

44 |

19.1~25.4 |

|

MT-VLD-20.3-76/6- |

20.3 |

76 |

20.3 |

56 |

19.1~25.4 |

|

MT-VLD-20.3-90/6- |

20.3 |

90 |

20.3 |

70 |

19.1~25.4 |

|

MT-VLD-25.4-45/4- |

25.4 |

45 |

25.4 |

25 |

25.4 以上 |

|

MT-VLD-25.4-53/4- |

25.4 |

53 |

25.4 |

33 |

25.4 以上 |

|

MT-VLD-25.4-64/4- |

25.4 |

64 |

25.4 |

44 |

25.4 以上 |

|

MT-VLD-25.4-76/6- |

25.4 |

76 |

25.4 |

56 |

25.4 以上 |

|

MT-VLD-25.4-90/6- |

25.4 |

90 |

25.4 |

70 |

25.4 以上 |