Halogen Free, Low Smoke, Highly Flame Retardant, Identification Tags

- MTVLN

- Halogen free low smoke emitting materials, ideal for identifying motor train unit, rail transit, aerospace and naval vessels

- Not necessary to disconnect the electrical return circuit when installing the identification maker labels

- Using the binding wire, easy to handle

- Temperature resistance, rated temperature 125°C

- Highly flame retardant, low toxicity index, meets international locomotive standards

- RoHS compliant, meets SONY SS-00259

- Permanent identification, not melting in high temp., not turning fragile in low temp., resistant to scrape, rub, abrasion

- Computer-printable, any character and logo are easy to design.

- Detailed

Halogen Free, Low Smoke, Highly Flame Retardant, Heat Shrinkable Identification Tags

Description

Features

● Halogen free low smoke emitting materials, ideal for identifying motor train unit, rail transit, aerospace and naval vessels

● Not necessary to disconnect the electrical return circuit when installing the identification maker labels

● Using the binding wire, easy to handle

● Temperature resistance, rated temperature 125°C

● Highly flame retardant, low toxicity index, meets international locomotive standards

● RoHS compliant, meets SONY SS-00259

● Permanent identification, not melting in high temp., not turning fragile in low temp., resistant to scrape, rub, abrasion

● Computer-printable, any character and logo are easy to design.

Rated Temperature

● Continuous operating temperature: -55°C~135°C/-67°F~275°F

● Max. storage and transportation temp.: ≤50°C /122°F

Standards

● Material standards: ASTM D 2671/DIN5510-2

● British/French smoke toxicity standards: BS 6853/NF F 16-101

● Color code soundness: SAE-AS 81531 and MIL-STD-202G/215K

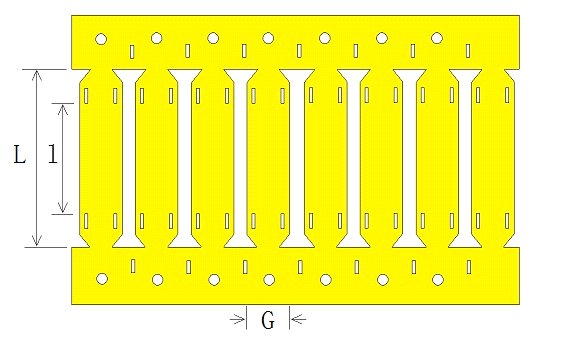

Structure

Technical Performance

|

Performance |

Indicators |

Test Method |

||

|

Typical properties |

Unit |

States |

||

|

Tensile Strength |

Mpa |

Unaged |

≥10.3 |

ASTM G 154,MIL-DTL-23053E |

|

Heat aged/ After fluids/UV aged |

≥6.9 |

|||

|

Elongation at break |

% |

Unaged |

≥200 |

|

|

Heat aged/ After fluid |

≥100 |

|||

|

Secant Modulus |

Mpa |

Unaged |

<173 |

ASTM D 882 |

|

Voltage Withstand |

V |

Unaged / After aged |

2500V, No breakdown in 60 sec. |

IEC 243,ASTM G 154 |

|

Dielectric Strength |

MV/m |

Before aged |

≥19.7 |

|

|

Heat aged/ After fluid/ UV aged |

≥15.8 |

|||

|

Volume Resistivity |

Ω.cm |

Unaged |

≥1014 |

IEC 93 |

|

Dielectric constant |

- |

Unaged |

- |

ASTM 150 |

|

Water Absorption |

- |

Unaged |

≤1.0 |

ASTM 570,23℃,24h |

|

Bare Copper Corrosion |

- |

Unaged |

No corrosion |

23℃,Rh 95±5%,24h |

|

Heat Shock |

- |

Unaged |

No cracks, flowing, dripping |

Wind to the specified mandrel, 225°C,4h |

|

Cold Flexibility |

- |

Unaged |

No cracks |

Wind to the specified mandrel,-30℃,1h |

|

Flammability |

- |

Unaged |

DIN 5510, S3 |

DIN 5510-2 |

|

Smoke Density |

- |

Unaged |

≤0.017 |

DIN 5510-2 |

|

Toxcity Index |

- |

Unaged |

≤1 |

BS 6853:1999 |

Dimensions

|

Order description |

Width G(mm) |

L Length(mm) |

Printed Characters |

Cable OD(mm) |

|

|

Height G |

Length l |

||||

|

MT-VLN-10.4-45/4- |

10.4 |

45 |

10.4 |

25 |

5.08~12.7 |

|

MT-VLN-10.4-53/4 |

10.4 |

53 |

10.4 |

33 |

5.08~12.7 |

|

MT-VLN-10.4-64/4- |

10.4 |

64 |

10.4 |

44 |

5.08~12.7 |

|

MT-VLN-10.4-76/6- |

10.4 |

76 |

10.4 |

56 |

5.08~12.7 |

|

MT-VLN-10.4-90/6- |

10.4 |

90 |

10.4 |

70 |

5.08~12.7 |

|

MT-VLN-15.0-45/4- |

15.0 |

45 |

15.0 |

25 |

12.7~19.1 |

|

MT-VLN-15.0-53/4- |

15.0 |

53 |

15.0 |

33 |

12.7~19.1 |

|

MT-VLN-15.0-64/4- |

15.0 |

64 |

15.0 |

44 |

12.7~19.1 |

|

MT-VLN-15.0-76/6- |

15.0 |

76 |

15.0 |

56 |

12.7~19.1 |

|

MT-VLN-15.0-90/6- |

15.0 |

90 |

15.0 |

70 |

12.7~19.1 |

|

MT-VLN-20.3-45/4- |

20.3 |

45 |

20.3 |

25 |

19.1~25.4 |

|

MT-VLN-20.3-53/4- |

20.3 |

53 |

20.3 |

33 |

19.1~25.4 |

|

MT-VLN-20.3-64/4- |

20.3 |

64 |

20.3 |

44 |

19.1~25.4 |

|

MT-VLN-20.3-76/6- |

20.3 |

76 |

20.3 |

56 |

19.1~25.4 |

|

MT-VLN-20.3-90/6- |

20.3 |

90 |

20.3 |

70 |

19.1~25.4 |

|

MT-VLN-25.4-45/4- |

25.4 |

45 |

25.4 |

25 |

≥25.4 |

|

MT-VLN-25.4-53/4- |

25.4 |

53 |

25.4 |

33 |

≥25.4 |

|

MT-VLN-25.4-64/4- |

25.4 |

64 |

25.4 |

44 |

≥25.4 |

|

MT-VLN-25.4-76/6- |

25.4 |

76 |

25.4 |

56 |

≥25.4 |

|

MT-VLN-25.4-90/6- |

25.4 |

90 |

25.4 |

70 |

≥25.4 |