Military Standard Cable Identification Tags

- MTVLA

- Military standard materials, ideal for aerospace, tank and submarines identifying purposes

- Side entry Marker tags to big size cables and wire bundles retrofit and repair capability, without broken circuit and run down the machines.

- Easy installation: only standard cable tie-wraps are needed to install marker tags. No extra steps required

- High temperature resistance, rated temp. 135°C

- High flame retardant, VW-1

- ROHS compliant

- Permanent identification, No melting at high temperature, no brittle in low temperature

- Computer-printable, any characters and logo are easy to design.

- Detailed

Military Standard Heat Shrinkable Cable Identification Tags

Description

MTVLA-military grade marker tags are made by means of bombardment and cross-linking of the environmentally friendly polyolefin with high energy electron beams. Marker tags are non-adhesive that can be used to identify EMU for high-speed rails, subways, submarines and aerospace. Market tags are attached on large cables and wire bundles with cable ties and keep permanent identification. The printed characters are amazingly abrasion resistant, even if washing agent or military purpose fuel oil corrosion happens, the color code soundness still meets American military standard SAE-AS 81531 and MIL-STD-202F/215J and keeps permanent identification.

Features

● Military standard materials, ideal for aerospace, tank and submarines identifying purposes

● Side entry Marker tags to big size cables and wire bundles retrofit and repair capability, without broken circuit and run down the machines.

● Easy installation: only standard cable tie-wraps are needed to install marker tags. No extra steps required

● High temperature resistance, rated temp. 135°C

● High flame retardant, VW-1

● ROHS compliant

● Permanent identification, No melting at high temperature, no brittle in low temperature

● Computer-printable, any characters and logo are easy to design.

Rated Temperature

● Continuous operating temperature: -55°C~135°C/-67°F~+275°F

● Max. storage and transportation temp.: ≤+50°C/+122°F

Standards

● AMS-DTL-23053/5, Compatible UL224

● Color code soundness: SAE-AS 81531 and MIL-STD-202F/215J

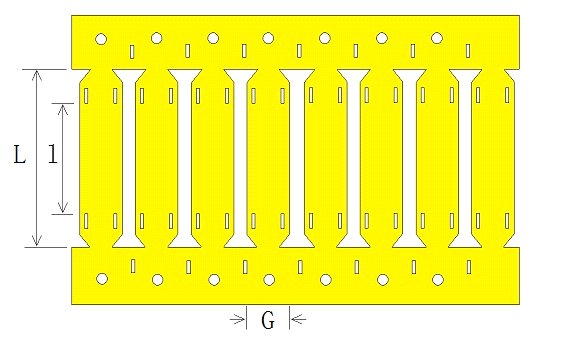

Structure

Technical Performance

|

Performance |

Indicators |

Test Method |

||

|

Typical properties |

Unit |

States |

||

|

Tensile Strength |

Mpa |

Unaged |

≥10.3 |

ASTM G 154,MIL-DTL-23053E |

|

Heat aged/ After fluids/UV aged |

≥6.9 |

|||

|

Elongation at break |

% |

Unaged |

≥200 |

|

|

Heat aged/ After fluid |

≥100 |

|||

|

Secant Modulus |

Mpa |

Unaged |

<173 |

ASTM D 882 |

|

Voltage Withstand |

V |

Unaged / After aged |

2500V,60S Breakdown |

IEC 243,ASTM G 154 |

|

Dielectric Strength |

MV/m |

Before aged |

≥19.7 |

|

|

Heat aged/ After fluid/ UV aged |

≥15.8 |

|||

|

Volume Resistivity |

Ω.cm |

Unaged |

≥1014 |

IEC 93 |

|

Dielectric constant |

- |

Unaged |

≤3.1 |

ASTM 150 |

|

Water Absorption |

- |

Unaged |

≤0.5 |

ASTM 570,23℃,24h |

|

Bare Copper Corrosion |

- |

Unaged |

No corrosion |

23℃,Rh 95±5%,24h |

|

Heat Shock |

- |

Unaged |

|

|

|

Cold Flexibility |

- |

Unaged |

No tracks ,no drops |

225℃,4h |

|

Flammability |

- |

Unaged |

No cracks |

-55℃,1h |

|

Smoke Density |

- |

Unaged |

VW-1 |

IEC 60332-1-3 Ed.1.0 b:2004 |

|

Toxcity Index |

- |

Unaged |

- |

DIN 5510-2 |

Dimensions

|

Order description |

Width G(mm) |

L Length(mm) |

Printed Characters |

Cable OD(mm) |

|

|

Height G |

Length l |

||||

|

MT-VLA-10.4-45/4- |

10.4 |

45 |

10.4 |

25 |

5.08~12.7 |

|

MT-VLA-10.4-53/4- |

10.4 |

53 |

10.4 |

33 |

5.08~12.7 |

|

MT-VLA-10.4-64/4- |

10.4 |

64 |

10.4 |

44 |

5.08~12.7 |

|

MT-VLA-10.4-76/6- |

10.4 |

76 |

10.4 |

56 |

5.08~12.7 |

|

MT-VLA-10.4-90/6- |

10.4 |

90 |

10.4 |

70 |

5.08~12.7 |

|

MT-VLA-15.0-45/4- |

15.0 |

45 |

15.0 |

25 |

12.7~19.1 |

|

MT-VLA-15.0-53/4- |

15.0 |

53 |

15.0 |

33 |

12.7~19.1 |

|

MT-VLA-15.0-64/4- |

15.0 |

64 |

15.0 |

44 |

12.7~19.1 |

|

MT-VLA-15.0-76/6- |

15.0 |

76 |

15.0 |

56 |

12.7~19.1 |

|

MT-VLA-15.0-90/6- |

15.0 |

90 |

15.0 |

70 |

12.7~19.1 |

|

MT-VLA-20.3-45/4- |

20.3 |

45 |

20.3 |

25 |

19.1~25.4 |

|

MT-VLA-20.3-53/4- |

20.3 |

53 |

20.3 |

33 |

19.1~25.4 |

|

MT-VLA-20.3-64/4- |

20.3 |

64 |

20.3 |

44 |

19.1~25.4 |

|

MT-VLA-20.3-76/6- |

20.3 |

76 |

20.3 |

56 |

19.1~25.4 |

|

MT-VLA-20.3-90/6- |

20.3 |

90 |

20.3 |

70 |

19.1~25.4 |

|

MT-VLA-25.4-45/4- |

25.4 |

45 |

25.4 |

25 |

>25.4 |

|

MT-VLA-25.4-53/4- |

25.4 |

53 |

25.4 |

33 |

>25.4 |

|

MT-VLA-25.4-64/4- |

25.4 |

64 |

25.4 |

44 |

>25.4 |

|

MT-VLA-25.4-76/6- |

25.4 |

76 |

25.4 |

56 |

>25.4 |

|

MT-VLA-25.4-90/6- |

25.4 |

90 |

25.4 |

70 |

>25.4 |