Teflon PTFE Heat Shrink Tubing

- TZRS-PTFE260 (1.7X 4X)

- Continuous operating temperature: -65°C~260°C

- Resistant to corrosion, strong acid, strong base, chemical reagents, and oil et

- Excellent Dielectric Insulation Properties

- Excellent electrical performance that does not change with the temperature and frequency

- Excellent mechanical performance, shock proof, high elasticity

- Ultra low friction coefficient highly flame retardant

- Flammability: VW-1

- Shrink Ratio: 1.7:1, 4:1

- Standard color: clear/transparent

- Detailed

Teflon PTFE Heat Shrink Tubing

Descriptions

A highly flame retardant heat shrinkable tubing manufactured from modified PTFE Provides insulation and mechanical protection in severe chemical and thermal environments Thin wall, high shrink ratio, flexible and transparent Major uses: electrical insulation, protection of electronic components, covering of hydraulic hose and couplings, prevention against contamination and corrosion High mechanical strength and extremely low coefficient of friction make it ideal for reducing damage to bearing shafts etc.

Features

● Continuous operating temperature: -65°C~260°C

● Resistant to corrosion, strong acid, strong base, chemical reagents, and oil et

● Excellent Dielectric Insulation Properties

● Excellent electrical performance that does not change with the temperature and frequency

● Excellent mechanical performance, shock proof, high elasticity

● Ultra low friction coefficient highly flame retardant

● Flammability: VW-1

● Shrink Ratio: 1.7:1, 4:1

● Standard color: clear/transparent

Technical Performance

|

Property |

standard |

Test data |

|

Tensile strength |

≥25MPa |

ASTM D 2671 |

|

elongation at break |

≥300% |

ASTM D 2671 |

|

Flammability |

VW-1 |

UL 224 |

|

dielectric strength |

≥26kV/mm |

IEC 60243 |

|

volume resistivity |

≥1014Ω.cm |

IEC 60093 |

|

copper corrosion |

Pass |

UL 224 |

|

water absorption |

<0.1% |

ASTM D 570 |

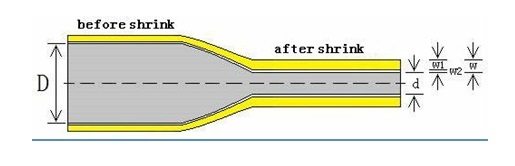

Structure

Dimensions(1.7:1)

|

Size |

As supplied D(mm) |

After full recovered(mm) |

Standard Package (M/roll, M/pcs) |

|

|

Diameter d |

Wall thickness w |

|||

|

Φ1.0 |

1.0±0.2 |

≤0.5 |

0.20±0.05 |

200 |

|

Φ1.5 |

1.5±0.2 |

≤0.9 |

0.20±0.05 |

200 |

|

Φ2.0 |

2.0±0.2 |

≤1.3 |

0.20±0.05 |

200 |

|

Φ2.5 |

2.5±0.2 |

≤1.5 |

0.20±0.05 |

200 |

|

Φ3.0 |

3.0±0.2 |

≤1.8 |

0.20±0.05 |

200 |

|

Φ3.5 |

3.5±0.2 |

≤2.0 |

0.25±0.05 |

100 |

|

Φ4.0 |

4.0±0.3 |

≤2.5 |

0.25±0.05 |

100 |

|

Φ4.5 |

4.5±0.3 |

≤2.8 |

0.25±0.05 |

100 |

|

Φ5.0 |

5.0±0.3 |

≤3.0 |

0.25±0.05 |

100 |

|

Φ6.0 |

6.0±0.3 |

≤3.8 |

0.25±0.05 |

100 |

|

Φ7.0 |

7.0±0.3 |

≤4.0 |

0.25±0.05 |

100 |

|

Φ8.0 |

8.0±0.3 |

≤4.8 |

0.25±0.05 |

1.0 |

|

Φ9.0 |

9.0±0.3 |

≤5.0 |

0.30±0.05 |

1.0 |

|

Φ10.0 |

10.0±0.3 |

≤5.8 |

0.30±0.05 |

1.0 |

|

Φ11.0 |

11.0±0.3 |

≤6.4 |

0.30±0.05 |

1.0 |

|

Φ12.0 |

12.0±0.3 |

≤7.0 |

0.30±0.05 |

1.0 |

|

Φ13.0 |

13.0±0.3 |

≤7.5 |

0.35±0.05 |

1.0 |

|

Φ14.0 |

14.0±0.3 |

≤8.0 |

0.35±0.05 |

1.0 |

Dimensions(4:1)

|

Size |

As supplied D(mm) |

After full recovered(mm) |

Standard package (M/Roll, M/Pcs) |

|

|

ID d |

wall thickness w |

|||

|

Φ2.0 |

≥2.0 |

≤0.46 |

0.25±0.05 |

200 |

|

Φ2.5 |

≥2.5 |

≤0.50 |

0.25±0.05 |

200 |

|

Φ3.0 |

≥3.0 |

≤0.66 |

0.25±0.05 |

200 |

|

Φ3.5 |

≥3.5 |

≤0.68 |

0.30±0.05 |

100 |

|

Φ4.0 |

≥4.0 |

≤0.81 |

0.35±0.05 |

100 |

|

Φ4.5 |

≥4.5 |

≤0.98 |

0.40±0.05 |

100 |

|

Φ5.0 |

≥5.0 |

≤1.23 |

0.40±0.05 |

100 |