Non-slip Textured Heat Shrink Tube

- Detailed

Non-slip Textured Heat Shrink Tube

Description

Non-slip textured heat shrink tubing is made of irradiation cross-linked polymer alloy, followed by a surface treatment. This products typically used for non-slip, non-skid decorative purpose for handles and grips on high grade fishing tackle, sport equipment, fitness equipment, daily supplies, various tools, kitchenware etc.

Features

● Flexible, fast shrinking

● Non slip, nice-looking, user-friendly

● Min shrink temperature:60

● Min full recovery temperature:105°C

● Continuous operating temperature:-55°C ~110°C

● Shrink ratios:2:1

● RoHS compliant

● Standard color: Black, Red, Yellow, Green, Blue

Technical Performance

|

Property |

Typical Data |

Test Method |

|

Tensile strength |

≥10.4MPa |

ASTM D 2671 |

|

Elongation |

≥200% |

ASTM D 2671 |

|

Longitudinal change |

-8%~+8% |

ASTM D 2671 |

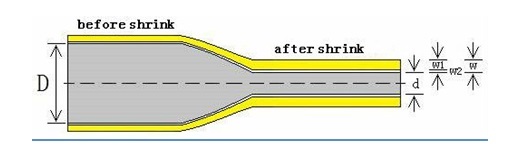

Structure

Dimensions

|

Size(mm) |

As supplied (mm) |

Recovered(mm) |

Standard |

||

|

Inner diameter |

Wall thickness |

Internal diameter |

Wall thickness |

||

|

φ15 |

≥15 |

0.45±0.15 |

8 |

0.85±0.15 |

1.0 |

|

φ20 |

≥20 |

0.50±0.15 |

11 |

0.90±0.15 |

0.8/1.0/1.6 |

|

φ22 |

≥22 |

0.50±0.15 |

12.5 |

0.90±0.15 |

0.8/1.0/1.6 |

|

φ25 |

≥25 |

0.50±0.15 |

14.5 |

1.00±0.15 |

0.8/1.0/1.6 |

|

φ28 |

≥28 |

0.50±0.15 |

15.5 |

1.00±0.15 |

0.8/1.0/1.6 |

|

φ30 |

≥30 |

0.60±0.15 |

17.5 |

1.20±0.15 |

0.8/1.0/1.6 |

|

φ35 |

≥35 |

0.60±0.15 |

20.0 |

1.20±0.15 |

0.8/1.0/1.6 |

|

φ40 |

≥40 |

0.60±0.15 |

23.0 |

1.20±0.15 |

0.8/1.0/1.6 |

|

φ45 |

≥45 |

0.65±0.15 |

25.0 |

1.25±0.15 |

0.8/1.0/1.6 |

|

φ50 |

≥50 |

0.65±0.15 |

28.0 |

1.25±0.15 |

0.8/1.0 |