EPDM Rubber Heat Shrink Tubing

- TZRS-EPDM150 (2X)

- Environmental friendly

- Outstanding low and high-temperature performance

- Higher shrink ratio than heat shrinkable silicone tubes

- Excellent acids and alkalis resistance

- Chemical solvent resistance

- Ultraviolet light and weather aging resistance

- Minimum shrink temperature:100°C

- Minimum full recovery temperature :135°C

- Continuous operating Temperature Range:-55~150°C

- Shrink Ratio: 2:1

- Use in 180-200°C

- Standard color: Black

- Detailed

EPDM Rubber Heat Shrink Tubing

EPDM Rubber Heat Shrink Tubing

Description

TZRS-EPDM150(2X) is a a new type of heat shrink tubing product, which is made through complicated formulation of EPDM rubber and special resins. When TZRS-EPDM150(2X) is heated, its inside diameter quickly recovers to half of the expanded inside diameter as supplied to tightly wrap and cover the electronic components inside. Compared to normal EPDM tubing, TZRS-EPDM150(2X), cross linked through the irradiation of electronic accelerators, has much better physical and mechanical performance, higher dielectric strength, abrasion and wear resistance. It finds wide applications in electronics, automotive, and consumer goods markets for jacketing and protection to cables, pipes, and connectors etc and protecting solder joints, wires, cables, terminals, connectors and various electronic apparatus.

Features

● Environmental friendly

● Outstanding low and high-temperature performance

● Higher shrink ratio than heat shrinkable silicone tubes

● Excellent acids and alkalis resistance

● Chemical solvent resistance

● Ultraviolet light and weather aging resistance

● Minimum shrink temperature:100°C

● Minimum full recovery temperature :135°C

● Continuous operating Temperature Range: -55~150°C

● Shrink Ratio: 2:1

● Use in 180-200°C

● Standard color: Black

Technical Performance

|

Properties |

Typical Data |

Test Method |

|

Tensile Strength |

≥14 Mpa |

GB/T 528 |

|

Ultimate Elongation |

≥400% |

GB/T 528 |

|

Tear Strength |

≥ 60Kn/M |

ASTM D 624 |

|

Dielectric Strength |

≥12kV/mm |

ASTM D149 |

|

Density |

1.1±0.05 g/cm3 |

ASTM D 792 |

|

Volume Resistivity |

≥2×1013 |

ASTM D 257 |

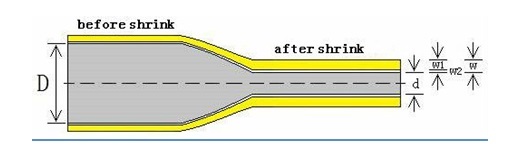

Structure

Dimensions

|

Size |

As Supplied(mm) D |

After Full Recovery(mm) |

Scope of Application (mm) |

Standard Package (m/spool) |

|

|

I.D.(Max.)d |

Wall Thickness w |

||||

|

φ6.0 |

≥6.0 |

≤3.0 |

0.8±0.10 |

3.5-6 |

50 |

|

φ8.0 |

≥8.0 |

≤4.0 |

0.9±0.10 |

4.5-8 |

50 |

|

φ10.0 |

≥10.0 |

≤5.0 |

1.2±0.10 |

5.5-9.5 |

50 |

|

φ12.0 |

≥12.0 |

≤6.0 |

1.2±0.10 |

6.5-11.5 |

20 |

|

φ16.0 |

≥16.0 |

≤8.0 |

1.5±0.15 |

8-15 |

20 |

|

φ20.0 |

≥20.0 |

≤10.0 |

1.5±0.15 |

11-19 |

20 |

|

φ30.0 |

≥30.0 |

≤15.0 |

1.8±0.15 |

17-29 |

20 |

|

φ40.0 |

≥40.0 |

≤20.0 |

2.0±0.15 |

22-38 |

20 |

|

φ50.0 |

≥50.0 |

≤25.0 |

2.0±0.20 |

27-48 |

10 |

|

φ60.0 |

≥60.0 |

≤30.0 |

2.0±0.30 |

32-58 |

10 |

|

φ70.0 |

≥70.0 |

≤35.0 |

2.0±0.30 |

38-68 |

10 |