Military Standard 135 °C (2X) (3X) (4X) Flame Retardant Heat Shrink Tubing

- Detailed

China Military Standard 135 °C Flame Retardant Heat Shrink Tubing Supplier

Description

135° C (2X)(3X)(4X) flame retardant heat shrinkable tube, made of radiation cross-linked polyolefin material, it has excellent physical and chemical electrical performance. Its main functions are electrical insulation of welding joints, rust and corrosion prevention, mechanical protection and wire harness protection, etc., which are widely used in the fields of electronics, communication, machinery and automobile manufacturing.

Features

● Executive standard: AMS-DTL-23053/5 compatible with UL 224, CAN/CSA C22.2-NO198.1-99

● Heat shrink ratio: 2:1, 3:1, 4:1

● Good elasticity, soft, flame retardant

● Shrinking temperature: 84℃ ~ 120℃

● Continuous operating temperature: -55 °C~ 135°C

● Environmental standards: RoHS

● Standard colors: black, other colors are available upon request.

Technical Data

|

Item |

Typical value |

Test method |

|

Tensile strength |

≥10.4MPa |

ASTM D 2671 |

|

Elongation at break |

≥200% |

ASTM D 2671 |

|

Tensile strength after thermal aging |

≥7.3MPa |

175℃×168h |

|

Elongation at break after thermal aging |

≥100% |

175℃×168h |

|

Axial rate of change |

-5%~+5% |

ASTM D 2671 |

|

Flame retardancy |

VW-1 |

ASTM D 2671 C |

|

Withstand voltage (rated voltage 600V) |

2500V,1min without breakdown |

UL 224 |

|

Breakdown strength |

≥19.7kV/mm |

ASTM D 149 |

|

Volume resistivity |

≥1014Ω.cm |

ASTM D 876 |

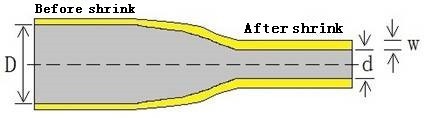

Structure

Dimension (Shrink Ratio: 2:1)

Size

As Supplied D(mm)

After Recovery(

mm )

Standard Package

(m/pcs)

inner diameter

wall thickness

Φ1.0/0.6

≥1.20

≤0.60

0.41±0.10

200

Φ1.5/0.8

≥1.60

≤0.80

0.41±0.10

200

Φ2.0/1.2

≥2.40

≤1.20

0.51±0.10

200

Φ3.0/1.6

≥3.20

≤1.60

0.51±0.10

200

Φ4.5/2.4

≥4.80

≤2.40

0.51±0.10

100

Φ6.0/3.2

≥6.40

≤3.20

0.64±0.10

100

Φ9.0/4.8

≥9.50

≤4.80

0.64±0.10

100

Φ12/6.4

≥12.70

≤6.40

0.64±0.10

100

Φ18/9.5

≥19.10

≤9.50

0.76±0.15

100

Φ25/12.7

≥25.40

≤12.70

0.89±0.15

50

Φ32/15.9

≥32.00

≤15.90

0.89±0.15

50

Φ38/19.1

≥38.00

≤19.10

1.00±0.15

50

Φ50/25.4

≥51.00

≤25.40

1.15±0.15

25

Φ75/38.1

≥76.00

≤38.10

1.27±0.20

25

Φ100/50.8

≥102.00

≤50.80

1.40±0.20

25

Φ120/63.5

≥125.00

≤63.50

1.40±0.25

25

Dimension (Shrink Ratio: 3:1)

Size

As Supplied D(mm)

After Recovery(

mm )

Standard Package

m/pcs

Inner diameter

Wall thickness

Φ1.5/0.5

≥1.5

≤0.50

0.45±0.10

200

Φ3.0/1.0

≥3.0

≤1.00

0.55±0.10

200

Φ4.5/1.5

≥4.5

≤1.50

0.60±0.10

100

Φ6.0/2.0

≥6.0

≤2.00

0.65±0.10

100

Φ9.0/3.0

≥9.0

≤3.00

0.75±0.15

50

Φ12/4

≥12.0

≤4.00

0.75±0.15

50

Φ15/5

≥15.0

≤5.00

0.80±0.15

50

Φ18/6

≥18.0

≤6.00

0.85±0.15

50

Φ24/8

≥24.0

≤8.00

1.00±0.20

25

Φ30/10

≥30.0

≤10.0

1.15±0.20

25

Φ39/13

≥39.0

≤13.0

1.50±0.20

25

Φ50/16

≥50.0

≤16.0

2.50±0.20

25

Φ60/20

≥60.0

≤20.0

2.60±0.20

25

Φ70/23

≥70.0

≤23.0

2.60±0.20

25

Φ80/26

≥80.0

≤26.0

2.60±0.20

25

Φ90/30

≥90.0

≤30.0

2.60±0.20

25

Φ100/33

≥100.0

≤33.0

2.60±0.20

25

Dimension (Shrink Ratio: 4:1)

Size

As Supplied D(mm)

After Recovery(

mm )

Standard Package

m/pcs

inner diameter

wall thickness

Φ3.2/0.8

≥3.2

≤0.8

0.60±0.20

100

Φ4.0/1.0

≥4.0

≤1.0

0.70±0.20

100

Φ6.0/1.5

≥6.0

≤1.5

0.78±0.25

100

Φ8.0/2.0

≥8.0

≤2.0

0.80±0.25

100

Φ10.0/2.5

≥10.0

≤2.5

0.85±0.25

100

Φ12.0/3.0

≥12.0

≤3.0

0.90±0.30

100

Φ16.0/4.0

≥16.0

≤4.0

1.00±0.30

100

Φ19.1/4.6

≥19.1

≤4.6

1.20±0.30

50

Φ24.0/6.0

≥24.0

≤6.0

1.25±0.30

50

Φ25.4/6.5

≥25.4

≤6.5

1.25±0.30

50

Φ30.0/7.5

≥30.0

≤7.5

1.25±0.30

50

Φ32.0/8.0

≥32.0

≤8.0

1.25±0.30

50

Φ38.1/9.5

≥38.1

≤9.5

1.30±0.30

50

Φ51.0/13.0

≥51.0

≤13.0

1.35±0.30

50

Φ64.0/16.0

≥64.0

≤16.0

1.45±0.40

25

Φ76.0/19.0

≥76.0

≤19.0

1.45±0.40

25

Φ95.0/24.0

≥95.0

≤24.0

1.45±0.40

25

Φ100.0/25.0

≥100.0

≤25.0

1.45±0.40

25

Φ115.0/29.0

≥115.0

≤29.0

1.50±0.40

25

Φ127.0/32.0

≥127.0

≤32.0

1.60±0.40

25

Φ150.0/38.0

≥150.0

≤38.0

1.60±0.40

25

Note: Special dimensions and packages are also available on request