Halogen-free Ultra-thin Flame Retardant Heat-shrink Tubing

- DBRS-125H (2X) CB

- Meets UL 224, CAN / CSA C22.2 NO198.1 -99

- Heat shrink ratio : 2:1

- Halogen-free , low-smoke emission , non-toxic , flexible , flame retardant , swiftly shrinking

- Min shrink temperature : 70 °C

- Min full recovery temperature : 120 °C

- Continuous operating temperature : -55 °C ~ 125 °C

- Environmental standards : RoHS , IPC/JEDEC-J-STD-709 Class H material

- Standard colors: black, white, red , yellow , green ,blue and other four international.

- standard colors. More colors are available upon request.

- Detailed

Halogen-free Ultra-thin Flame Retardant Heat-shrink Tubing

Description

Halogen-freeultra-thin flame retardant heat-shrink tubing, made of radiation cross-linkedpolyolefin, carries excellent physicochemical and electrical properties.Typical applications include insulation of electrical connections, rust andcorrosion resistance for soldered connections or joints, mechanical and wiringharness protection. This product is widely used in the automotive, agriculturaland household Pipe Benders protection, electronics, life consumables,decoration and lighting, communications, ship, aircraft manufacturing and otherfields.

Features

● Meets UL 224, CAN / CSA C22.2 NO198.1 -99

● Heat shrink ratio : 2:1

● Halogen-free , low-smoke emission , non-toxic , flexible , flame retardant , swiftly shrinking

● Min shrink temperature : 70 °C

● Min full recovery temperature : 120 °C

● Continuous operating temperature : -55 °C ~ 125 °C

● Environmental standards : RoHS , IPC/JEDEC-J-STD-709 Class H material

● Standard colors: black, white, red , yellow , green , blue and other four international standard colors. More colors are available upon request.

Technical Data

Properties

Typical

Data

Test

Method

Tensile strength

≥10.4MPa

ASTM D 2671

Elongation

≥200%

ASTM D 2671

Tensile strength after heat aging

≥7.3MPa

158℃×168h

Elongation after heat aging

≥100%

158℃×168h

Longitudinal change

-5%~+5%

ASTM D 2671

Flammability

VW-1

ASTM D 2671 C

Voltage withstand(Rated voltage 600V)

1500V,1min, without breakdown

UL 224

Heat shock

No cracking, no dripping

UL 224,250℃×4h

Dielectric strength

≥15kV/mm

ASTM D 149

Volume resistivity

≥1014Ω.cm

IEC 60093

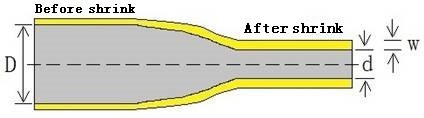

Structure

Dimension

Size(mm)

As

supplied D(mm)

After

full recovered (mm)

Standard

Package

(M/Roll)

Inner diameter d

Wall thickness w

Φ0.6/0.40

0.9±0.2

≤0.40

0.20±0.10

200

Φ0.8/0.50

1.1±0.2

≤0.50

0.20±0.10

200

φ1.0/0.65

1.4±0.2

≤0.65

0.20±0.10

200

φ1.5/0.85

1.9±0.2

≤0.85

0.20±0.10

200

φ2.0/1.00

2.4±0.2

≤1.00

0.22±0.10

200

φ2.5/1.30

2.9±0.2

≤1.30

0.25±0.10

200

φ3.0/1.50

3.4±0.2

≤1.50

0.28±0.10

200

φ3.5/1.80

3.9±0.2

≤1.80

0.28±0.10

200

φ4.0/2.00

4.4±0.2

≤2.00

0.30±0.10

200

φ4.5/2.30

4.9±0.2

≤2.30

0.30±0.10

200

φ5.0/2.50

5.5±0.2

≤2.50

0.32±0.10

100

φ6.0/3.00

6.5±0.2

≤3.00

0.32±0.10

100

φ7.0/3.50

7.5±0.3

≤3.50

0.32±0.10

200

φ8.0/4.00

8.5±0.3

≤4.00

0.32±0.10

200

φ9.0/4.50

9.5±0.3

≤4.50

0.35±0.10

200

φ10/5.00

10.5±0.3

≤5.00

0.35±0.10

200

φ11/5.50

11.5±0.3

≤5.50

0.40±0.10

200

φ12/6.00

12.5±0.3

≤6.00

0.40±0.10

200

φ13/6.50

13.5±0.3

≤6.50

0.40±0.10

200

φ14/7.00

14.5±0.3

≤7.00

0.40±0.10

200

φ15/7.50

15.5±0.4

≤7.50

0.40±0.10

200

φ16/8.00

16.5±0.4

≤8.00

0.40±0.10

200

φ17/8.50

17.5±0.4

≤8.50

0.40±0.10

200

φ18/9.00

18.5±0.4

≤9.00

0.42±0.10

200

φ20/10.0

20.5±0.5

≤10.0

0.45±0.10

200

φ22/11.0

22.5±0.5

≤11.0

0.45±0.10

100

φ25/12.5

25.5±0.5

≤12.5

0.45±0.10

100

φ28/14.0

28.5±0.5

≤14.0

0.45±0.10

100

Note: non standard dimensions and packages are also available on request