Low Temperature Flame Retardant Heat Shrink Tubing

- Detailed

Low Temperature Flame Retardant Heat Shrink Tubing

Description

VolsunDBRS-125G(2X)LS,made of radiationcross-linked polyolefin, has excellent physicochemical and electricalproperties.It can reliably insulate cable and wire splices andterminations, effectively protect soldered joint and provides good mechanicalprotection for wire harness in electronic, communications, automotive, shippingand aircraft manufacturing industries.

Features

● Shrink ratio:2:1

● Flexible ,flame retardant, environmentally friendly,low temperature shrinkable

● Shrink temperature:65°C~95°C

● Continuous operating temperature:-55°C~125°C

● RoHS compliant

● Standard color:black

Technical Performance

Properties

Typical

data

Test

Method

Tensile strength

≥12MPa

ASTM D 2671

Elongation

≥400%

ASTM D 2671

Tensile strength after heat aging

≥11MPa

158°C×168h

Elongation after heat aging

≥200%

158°C×168h

Longitudinal change

-5%~+5%

ASTM D 2671

Flammability

VW-1

ASTM D 2671 C

Voltage withstand(Rated voltage 600V)

2500V,1min no breakdown

UL 224

Heat shock

No tracks,No drippings

UL 224,250°C×4h

Dielectric strength

≥20kV/mm

IEC 60243

Volume resistivity

≥1014Ω.cm

ASTM D 2671

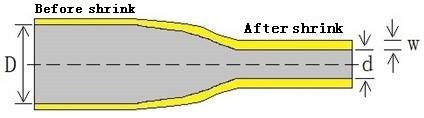

Structure

Dimension

Size(mm)

As

supplied D(mm)

After

full recovery(mm)

Standard

package

(M/spool)

Inner diameter d

Wall thickness w

φ1.6

≥1.6

≤0.80

≥0.50

200

φ2.4

≥2.4

≤1.20

≥0.50

200

φ3.2

≥3.2

≤1.60

≥0.50

200

φ4.8

≥4.8

≤2.40

≥0.50

100

φ6.4

≥6.4

≤3.20

≥0.60

100

φ8.0

≥8.0

≤4.00

≥0.60

100

φ9.5

≥9.5

≤4.80

≥0.60

100

φ12.7

≥12.7

≤6.40

≥0.60

50

φ16.0

≥16.0

≤8.00

≥0.60

50

φ19.1

≥19.1

≤9.50

≥0.80

50

φ25.4

≥25.4

≤12.7

≥0.90

50

φ31.8

≥31.8

≤15.9

≥0.90

50

φ38.1

≥38.1

≤19.1

≥1.00

50

φ50.8

≥50.8

≤25.4

≥1.10

50

Note: non standard dimensions and packages are also available on request