Yellow/Green Stripped Heat Shrink Tubing

- Detailed

Yellow/Green Stripped Heat Shrink Tubing

Description

Description

Volsun DBRS-125G(2X)(3X)YG is made through co-extrusion of two differentcolored specially formulated masterbatches of polyolefin and irradiationcross-linking process with electronic accelerators .Typical applicationsinclude identification of earth wire or other special cables and wires.

Features

● Shrink Ratio:2:1,3:1

● Highly flame retardant、environment friendly

● Shrink temperature:70℃~125℃

● Continuous operating temperature:-55℃~125℃(2:1) -55℃~135℃(3:1)

● RoHS compliant

● Standard colors:Yellow/Green Striped

Technical Properties

Properties

Typical

Data

Test

Methods/conditions

Tensile strength

≥10.4MPa

ASTM D 2671

Elongation

≥300%

ASTM D 2671

Tensile strength after heat aging

≥7.3MPa

158℃×168h

Elongation after heat aging

≥100%

158℃×168h

Longitudinal change

-8%~+8%

ASTM D 2671

Flammability

VW-1

ASTM D 2671 C

Voltage withstand(Rated voltage 600V)

2500V,1min, no break down

UL 224

Heat shock

No cracks,no dripping

UL 224,250℃×4h

Dielectric strength

≥15kV/mm

ASTM D 149

Volume resistivity

≥1014Ω.cm

IEC 60093

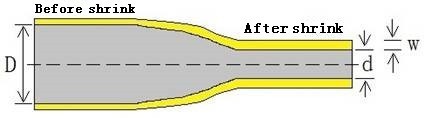

Structure

Dimensions (2:1 )

Size(mm)

As

supplied D(mm)

After

full recovery (mm)

Standard

Package

(M/Roll)

Inner diameter d

Wall thickness w

φ1.0/0.70

1.5±0.3

≤0.70

0.28±0.10

200

φ1.5/0.90

2.0±0.3

≤0.90

0.30±0.10

200

φ2.0/1.00

2.5±0.3

≤1.00

0.35±0.10

200

φ2.5/1.30

3.0±0.3

≤1.30

0.36±0.10

200

φ3.0/1.50

3.5±0.4

≤1.50

0.38±0.10

200

φ3.5/1.80

4.0±0.4

≤1.80

0.40±0.10

200

φ4.0/2.00

4.5±0.4

≤2.00

0.45±0.10

200

φ4.5/2.30

5.0±0.4

≤2.30

0.45±0.10

100

φ5.0/2.50

5.5±0.4

≤2.50

0.45±0.10

100

φ6.0/3.00

6.5±0.4

≤3.00

0.50±0.10

100

φ7.0/3.50

7.5±0.4

≤3.50

0.50±0.10

100

φ8.0/4.00

8.5±0.5

≤4.00

0.55±0.10

100

φ9.0/4.50

9.5±0.5

≤4.50

0.55±0.10

100

φ10/5.00

10.5±0.5

≤5.00

0.55±0.10

100

φ11/5.50

11.5±0.5

≤5.50

0.60±0.10

100

φ12/6.00

12.5±0.5

≤6.00

0.60±0.10

100

φ13/6.50

13.5±0.5

≤6.50

0.60±0.10

100

φ14/7.00

14.5±0.5

≤7.00

0.65±0.10

100

φ15/7.50

15.5±0.6

≤7.50

0.70±0.10

100

φ16/8.00

16.5±0.6

≤8.00

0.70±0.10

100

φ17/8.50

17.5±0.6

≤8.50

0.70±0.10

100

φ18/9.00

19.0±0.7

≤9.00

0.70±0.15

100

φ20/10.0

22.0±0.7

≤10.0

0.75±0.15

100

φ22/11.0

24.0±0.7

≤11.0

0.80±0.15

100

φ25/12.5

26.0±0.7

≤12.5

0.90±0.15

50

φ28/14.0

29.0±0.7

≤14.0

0.90±0.15

50

φ30/15.0

31.5±0.7

≤15.0

0.95±0.15

50

φ35/17.5

36.5±0.7

≤17.5

0.95±0.15

50

φ40/20.0

41.5±0.7

≤20.0

1.00±0.20

50

Φ45/22.5

46.0±0.7

≤22.5

1.00±0.20

25

φ50/25.0

51.0±0.7

≤25.0

1.00±0.20

25

φ60/30.0

≥60.0

≤30.0

1.10±0.20

25

φ70/35.0

≥70.0

≤35.0

1.20±0.20

25

φ80/40.0

≥80.0

≤40.0

1.30±0.20

25

φ90/45.0

≥90.0

≤45.0

1.50±0.20

25

φ100/50.0

≥100.0

≤50.0

1.65±0.20

25

φ120/60.0

≥120.0

≤60.0

1.70±0.20

15

φ150/75.0

≥150.0

≤75.0

1.70±0.20

15

φ180/90.0

≥180.0

≤90.0

1.75±0.20

15

Dimensions (3:1)

Size(mm)

As

Supplied D (mm)

After

full recovery(mm)

Standard

package

(M/Rolll)

Inner diameter d

Wall thickness w

φ1.5

≥1.6

≤0.50

≥0.50

200

φ2.4

≥2.4

≤0.80

≥0.50

200

φ3.0

≥3.2

≤1.00

≥0.55

200

φ4.5

≥4.8

≤1.50

≥0.60

100

φ6.0

≥6.4

≤2.00

≥0.65

100

φ9.0

≥9.5

≤3.00

≥0.75

100

φ12.0

≥12.7

≤4.00

≥0.75

50

φ18.0

≥19.1

≤6.00

≥0.85

50

φ24.0

≥25.4

≤8.00

≥1.00

50

φ39.0

≥39.0

≤13.0

≥1.15

50

Note: Non-standard dimensions and packages are available on request