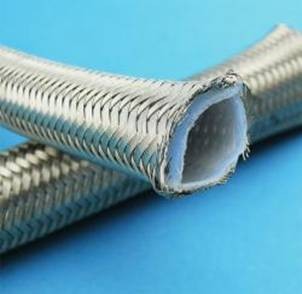

Stainless Steel Braided Teflon (PTFE) Hose

- Detailed

Description

Description

Braided Teflon (PTFE) hose is an extruded Teflon corewith an outer stainless steel braid for strength. Teflon (PTFE) hose isflexible and strong , when combined with stainless steel, can perform under high pressure andcontinuous flexing and vibration conditions. With a wide range of chemicalscompatibility teflon hose can handle an almost endless variety of fluids atextremes of pressure and temperature. Almost no substance can stick to teflon.This property ensures the purity of any product transferred via a teflon hose.It also allows for alternate use with different products. Typical applicationsinclude high pressure &high temperature for brake, clutch and powersteering lines off-road brake, transmission, clutch, gauge, nitrous oxide,hydraulic and air conditioning.

Features

- High temperature resistant, operating temperature: -50℃~210℃

- Corrosion resistant to strong acid, strong base, chemical reagent, oil etc

- Transient temperature resistant range: -70℃~+260℃

Dimensions

|

Size(inch) |

Inner Diameter(mm) |

Outer diameter(mm) |

Operating pressure(kg/cm2) |

Burst pressure |

Weight (g/m) |

Bend radius (mm±3mm) |

|

3/16 |

3.20~ 3.35 |

5.85~ 6.30 |

285 |

832 |

89 |

50 |

|

1/4 |

4.64~ 5.17 |

7.29~ 8.48 |

256 |

625 |

104 |

76 |

|

5/16 |

5.96~ 6.83 |

8.22~ 9.46 |

232 |

552 |

122 |

81 |

|

3/8 |

7.55~ 8.39 |

10.31~11.71 |

194 |

540 |

155 |

131 |

|

1/2 |

9.91~10.67 |

12.73~14.18 |

162 |

450 |

185 |

182 |

|

5/8 |

12.54~13.37 |

15.72~16.73 |

139 |

425 |

220 |

211 |

|

3/4 |

15.19~16.59 |

18.57~20.18 |

101 |

385 |

252 |

252 |

|

1 |

21.39~23.05 |

24.59~27.03 |

93 |

240 |

406 |

421 |

Note: above is just our standard dimensions. If you failed to find your required dimensions, please contact us with your specific requirements.

Benefits

Stainless steel braided teflon hoses could very well be the easiest and least expensive way to upgrade your braking system.

In any braking system there is a flex----in the pedal, in the caliper, but most of the flex is in the hose. Every time you should push on your brake pedal, up to 6.7kN(1500Ibf) of pressure moves brake fluid from the master cylinder to the wheel slave cylinders at the front and back of the car(in the form of calipers or drum brake wheel cylinders). Most of the pipe work from the master cylinder to the slave cylinders is made from rigid steel or cupronickel lines. Unfortunately, these solid lines cannot complete the journey all the way to the slave cylinders because movement in the line is necessary to connect a non-moving part(the chassis) to a moving part(the brake assembly attached to the wheel). These connecting hoses are made from rubber with nylon braiding. Even with nylon braiding inside the hose, the pressure exerted inside the hose will make it expand. This expansion weakens the braking system as it allows for loss of energy meant for the slave cylinders. In a stainless steel braided teflon hose, this expansion is reduced dramatically. This means quicker pedal response and shorter braking distances.

Stainless steel braided teflon hoses come with all necessary adapters and fittings for direct replacement with no modifications.

Stainless steel and teflon both handle heat very well and tend to maintain a constant cross section under these conditions.

Rubber hoses, which have been left on the car far too long, can, when swelling up, swell internally shutting off the fluid path. Master cylinder pressure can force fluid through, but the fluid cannot return once the brakes have been released resulting in brake lock. Stainless steel braided teflon hoses overcome this problem.

One word of caution: stainless steel braided teflon hoses whilst flexible in the sense that they can wiggle around, are definitely not flexible in stretch!It is important to ensure that all necessary precautions are taken when changing from rubber(which are very forgiving in stretch) to stainless steel braided teflon hoses.

Also, should a rubber hose become crushed in the suspension components as they move through their normal travel(heaven forbid!) it would resume its shape later. The outer braided sheath of stainless steel braided teflon hoses would stay crushed and may impede fluid flow.

More seriously, should a rubber hose be replaced with a stainless steel braided teflon hose, which is too short for the job, it may become strained on full suspension travel and if it does, there is a very high and real risk of an end fitting being pulled off. A rubber hose is more likely to accommodate a small amount of strain.

The following points should help to ensure your stainless steel braided teflon hoses give long and trouble free service.

- Always check that suspension bump and rebound stops are in good condition and actually hit the restraint when and where they should do.

- Ensure the stainless steel braided steel teflon hose has more than ample free movement in all extremes of travel. It is not sufficient to match the new hose with the rubber hose. The rubber hose fitted may have been too short but survived due to its elastic nature.

- Always check full and free movement of the steering, with the wheels fitted, to ensure there is no circumstance under which the hose can become trapped, rub or chaff on moving parts, particularly the wheel rim.