Silicon Rubber Overhead Line Cover

- Detailed

Silicon Rubber Overhead Line Cover

Description

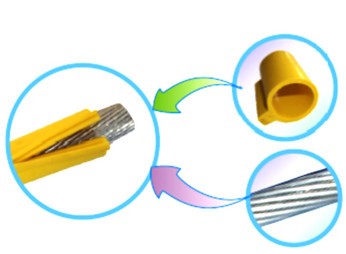

RUBNS-OLC The innovative product design, ease of installation. Use silicon rubber material, anti-aging, corrosion resistance, with good resistance to corona resistance, high temperature performance, especially suitable for the protection of the bare wire. Widely used in substation protection works and railway catenary system, a significant effect in the cross-lines.

Technical Performance

|

Serial No. |

Properties |

Unit |

Standard Data |

Test Results |

Test Methods |

|

1 |

Electrical Strength Test |

kV/mm |

≥20 |

22 |

GB/T 1408.1-2006 |

|

2 |

Volume Resistivity |

Ω·cm |

≥1×1014 |

2×1014 |

GB/T 1410-2006 |

|

3 |

Dielectric Constant |

2~3 |

2.3 |

GB/T 1409-2006 |

|

|

4 |

Shore Hardness |

A |

70±5 |

71 |

GB/T 531 |

|

5 |

Mechanical Properties |

GB/T 528 |

|||

|

5.1 |

Before heat ageing |

||||

|

Tensile Strength |

MPa |

≥4.0 |

5.5 |

||

|

Elongation at break |

% |

≥200 |

243 |

||

|

5.2 |

After Heat ageing(180℃, 7d) |

% |

±30 |

13 |

|

|

Tensile Strength Change Elongation Change |

% |

±30 |

-22 |

||

|

6 |

Low Temperature Elongation(-15℃, 2h) |

% |

≥20 |

190 |

GB/T 2951.4-1997 |

|

7 |

Low Temperature Flexibility(-50℃, 4h) |

- |

No cracks |

No cracks |

UL224-2004 |

|

8 |

High Temperature Crack Resistance(155℃, 2h) |

- |

No cracks |

No cracks |

GB/T2951.6-1997 |

Structure

Dimensions

|

LJ Stranded Wire Cross-sectional Area(Nominal) |

O.D. Of LJ Stranded Wire(mm) |

Silicone Rubber Sleeving Covers Models(mm) |

|

50 |

9.00 |

Ф12 |

|

70 |

10.80 |

Ф12 |

|

95 |

12.48 |

Ф17 |

|

120 |

14.25 |

Ф17 |

|

150 |

15.75 |

Ф20 |

|

185 |

17.50 |

Ф20 |

|

210 |

18.75 |

Ф24.2 |

|

240 |

20.00 |

Ф24.2 |

|

300 |

22.40 |

Ф24.2 |

|

400 |

25.90 |

Ф30 |

|

500 |

29.12 |

Ф32 |

|

630 |

32.67 |

Ф35 |

|

800 |

36.90 |

Ф39.8 |

|

LGJ Stranded Wire& LGJF Stranded Wire Cross-sectional Area(Nominal) |

O.D. Of LJ Stranded Wire(mm) |

Silicone Rubber Sleeving Covers Models(mm) |

|

35 |

-- |

Ф12 |

|

50 |

-- |

Ф15.6 |

|

70/10 |

11.4 |

Ф17 |

|

70/40 |

13.6 |

Ф17 |

|

95/15 |

13.61 |

Ф17 |

|

95/20 |

13.87 |

Ф17 |

|

95/55 |

16 |

Ф17 |

|

120/7 |

14.5 |

Ф20 |

|

120/20 |

15.07 |

Ф20 |

|

120/25 |

15.74 |

Ф20 |

|

120/70 |

18 |

Ф20 |

|

150/8 |

16 |

Ф20 |

|

150/20 |

16.67 |

Ф20 |

|

150/25 |

17.1 |

Ф20 |

|

150/35 |

17.5 |

Ф20 |

|

LGJJ-120 |

15.5 |

Ф20 |

|

LGJJ-150 |

17.5 |

Ф20 |

|

LGJQ-150 |

16 |

Ф20 |

|

185/10 |

18 |

Ф24.2 |

|

185/25 |

18.9 |

Ф24.2 |

|

185/30 |

18.88 |

Ф24.2 |

|

185/45 |

19.6 |

Ф24.2 |

|

210/10 |

19 |

Ф24.2 |

|

210/25 |

19.98 |

Ф24.2 |

|

210/35 |

20.38 |

Ф24.2 |

|

210/50 |

20.86 |

Ф24.2 |

|

240/30 |

21.6 |

Ф24.2 |

|

240/40 |

21.66 |

Ф24.2 |

|

240/55 |

22.4 |

Ф24.2 |

|

LGJJ-185 |

19.6 |

Ф24.2 |

|

LGJJ-240 |

22.4 |

Ф24.2 |

|

LGJQ-185 |

18.4 |

Ф24.2 |

|

LGJQ-240 |

21.6 |

Ф24.2 |

|

400/20 |

26.91 |

Ф32 |

|

400/25 |

26.64 |

Ф32 |

|

400/35 |

26.82 |

Ф32 |

|

400/50 |

27.63 |

Ф32 |

|

400/65 |

28 |

Ф32 |

|

400/95 |

29.14 |

Ф32 |

|

500/35 |

30 |

Ф32 |

|

500/45 |

30 |

Ф32 |

|

500/65 |

30.96 |

Ф32 |

|

800/55 |

38.4 |

Ф39.8 |

|

800/70 |

38.58 |

Ф39.8 |

|

800/100 |

38.58 |

Ф39.8 |

Voltage-Ratings/Wall

Voltage(KV)

≤10KV

≤35KV

≤110KV

≤220KV

Thickness

2.0±0.3mm

2.6±0.4mm

4.0±0.5mm

6.0±1.0mm

Application Cases

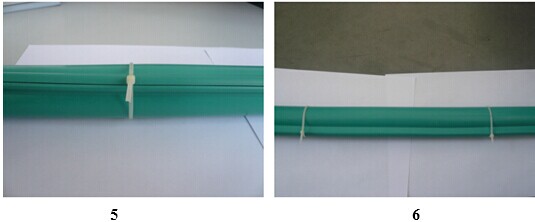

Installation Instructions

● Clean the inside of the RUBNS-OLC with cleaning cloth and alcohol fluids until the inside is clean without dust;

● Connect the pointed plastic mouth to the body of RTV silicone rubber adhesive bottle. See illustration 1 above.

● Smear RTV silicone rubber adhesive all over the concave channel of the RUBNS-OLC uniformly as showed the 2 above

● Uniformly smear the two flat fringes of the concave channel with RTV silicone rubber adhesive as the illustration 3 shows

● Connect the bulging part of the RUBNS-OLC on one side into the concave channel of the other side and squeeze the connecting part from one end to the other as illustration 4 indicates.