NS-GF200RUB-N Silicone Rubber Fiberglass Sleeve

- Detailed

NS-GF200RUB-N

Silicone Rubber Fiberglass Sleeve—Inner Braided fiberglass Outside Silicone Rubber

Description

Silicone rubber fiberglass sleeve is made of alkali-free fiberglass woven into a tube, coated with a layer of silicone rubber composite material on the outer layer of the tube, and then heated and cured. With high dielectric strength, good flexibility, heat resistance aging, flame retardant, temperature resistance up to 200℃.

Widely used in household electrical appliances, motors, electromechanical equipment, vehicles, ships and other circuit insulation protection.

Features

Operating temperature:-40°C~200°C

Standard color: White, red, yellow, blue, green, black,other colors on quest

Technical Performance

Type

Breakdown voltage(V)

Volume resistivity

(Ω.cm)

Temperature

resistance

Flammability

Average

Minim

4.0KV

UL94

4000 3000 1011 -40℃~200℃

HB Grade

7.0KV

7000

5000

1011

-40℃~200℃

UL 94

HB Grade

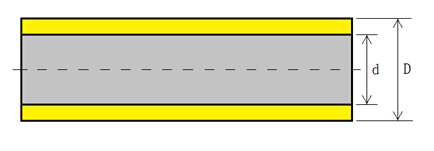

Structure

Dimension

|

|

ID(mm) |

|

|

Wall Thickness(mm) |

Packaging |

|

|

Size |

|

Tolerance |

4000V |

|

7000V |

(Roll/M) |

|

Φ0.5 |

|

-0.1~+0.20 |

0.40±0.1 |

|

0.45±0.1 |

200 |

|

Φ0.8 |

|

-0.1~+0.20 |

0.40±0.1 |

|

0.45±0.1 |

200 |

|

Φ1.0 |

|

-0.1~+0.20 |

0.40±0.1 |

|

0.45±0.1 |

200 |

|

Φ1.5 |

|

-0.1~+0.25 |

0.45±0.1 |

|

0.50±0.1 |

200 |

|

Φ2.0 |

|

-0.1~+0.25 |

0.45±0.1 |

|

0.50±0.1 |

100 |

|

Φ2.5 |

|

-0.1~+0.25 |

0.45±0.1 |

|

0.50±0.1 |

100 |

|

Φ3.0 |

|

-0.1~+0.25 |

0.45±0.1 |

|

0.50±0.1 |

100 |

|

Φ3.5 |

|

-0.1~+0.35 |

0.50±0.1 |

|

0.55±0.1 |

100 |

|

Φ4.0 |

|

-0.1~+0.35 |

0.50±0.1 |

|

0.55±0.1 |

100 |

|

Φ4.5 |

|

-0.1~+0.35 |

0.50±0.1 |

|

0.55±0.1 |

100 |

|

Φ5.0 |

|

-0.1~+0.35 |

0.50±0.1 |

|

0.55±0.1 |

100 |

|

Φ5.5 |

|

-0.1~+0.40 |

0.55±0.1 |

|

0.60±0.1 |

100 |

|

Φ6.0 |

|

-0.2~+0.40 |

0.55±0.1 |

|

0.60±0.1 |

100 |

|

Φ7.0 |

|

-0.2~+0.50 |

0.55±0.1 |

|

0.60±0.1 |

100 |

|

Φ8.0 |

|

-0.2~+0.50 |

0.55±0.1 |

|

0.65±0.1 |

50 |

|

Φ9.0 |

|

-0.2~+0.50 |

0.55±0.1 |

|

0.65±0.1 |

50 |

|

Φ10.0 |

|

-0.2~+0.70 |

0.65±0.15 |

|

0.70±0.15 |

50 |

|

Φ11.0 |

|

-0.2~+0.70 |

0.65±0.15 |

|

0.70±0.15 |

50 |

|

Φ12.0 |

|

-0.2~+0.70 |

0.65±0.15 |

|

0.70±0.15 |

50 |

|

Φ13.0 |

|

-0.3~+0.80 |

0.70±0.15 |

|

0.75±0.15 |

50 |

|

Φ14.0 |

|

-0.3~+0.80 |

0.70±0.15 |

|

0.75±0.15 |

50 |

|

Φ15.0 |

|

-0.3~+0.80 |

0.70±0.15 |

|

0.75±0.15 |

50 |

|

Φ16.0 |

|

-0.3~+0.80 |

0.70±0.15 |

|

0.75±0.15 |

50 |

|

Φ17.0 |

|

-0.5~+1.00 |

0.75±0.20 |

|

0.80±0.20 |

30 |

|

Φ18.0 |

|

-0.5~+1.00 |

0.75±0.20 |

|

0.80±0.20 |

30 |

|

Φ19.0 |

|

-0.5~+1.00 |

0.80±0.20 |

|

0.85±0.20 |

30 |

|

Φ20.0 |

|

-0.5~+1.00 |

0.80±0.20 |

|

0.85±0.20 |

30 |

|

Φ22.0 |

|

-0.5~+1.00 |

0.85±0.20 |

|

0.90±0.20 |

30 |

|

Φ25.0 |

|

-0.5~+1.00 |

0.95±0.20 |

|

1.05±0.20 |

30 |

|

Φ30.0 |

|

-0.5~+2.00 |

1.05±0.25 |

|

1.15±0.25 |

30 |