NS-GF200RUB-W Inner Silicon Rubber Outside Fiberglass Sleeve

- Detailed

Silicone Rubber Fiberglass Sleeves

Description

Silicone rubber glass fiber sleeve is woven from alkali-free glass fiber into a tube, coated with silicone rubber on the outer layer of the tube, and then cured. It has high dielectric strength, good softness, heat aging, oil resistance, flame retardant, and temperature resistance up to 200℃. Widely used for circuit insulation protection of new energy vehicles, special vehicles, rail transit, military industry and aerospace.

Features

- Operating temperature: -40℃ ~ 200℃

- Environmental protection standards: RoHS, REACH

- Standard color: transparent, white, black, red, yellow, blue, green, orange, other colors can be customized.

Technical Performance

Properties

Typical Data

Test method

Appearance

No leakage,

cracking,etc

GB/T 7113.1-2014

Hydrolysis of coating

No coating

displacement, adhesion,etc

GB/T 7113.2-2014

Cold bending

-40℃, 4h, no cracks, coating peeling and delamination

IEC60684

Flame retardant

HB

UL94

Breakdown voltage

Reference

standards

GB/T 7113.2-2014

Tear strength

≥50N/mm

/

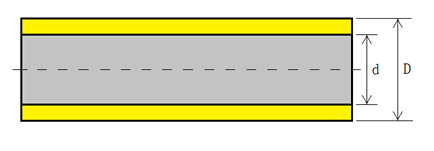

Structure

Dimensions

Size( mm )

Wall thickness W(mm)

Standard Packing

Diameter

(mm)

Tolerance

(mm)

1500V

2500V

4000V

7000V

m/ea

Φ2.0

-0.10~0.30

0.35±0.10

0.40±0.10

0.45±0.10

0.50±0.10

100

Φ2.5

-0.10~0.30

0.35±0.10

0.40±0.10

0.45±0.10

0.50±0.10

100

Φ3.0

-0.10~0.30

0.35±0.10

0.40±0.10

0.45±0.10

0.50±0.10

100

Φ3.5

-0.10~0.40

0.40±0.10

0.45±0.10

0.50±0.10

0.55±0.10

100

Φ4.0

-0.10~0.40

0.40±0.10

0.45±0.10

0.50±0.10

0.55±0.10

100

Φ4.5

-0.10~0.40

0.40±0.10

0.45±0.10

0.50±0.10

0.55±0.10

100

Φ5.0

-0.10~0.40

0.40±0.10

0.45±0.10

0.50±0.10

0.55±0.10

100

Φ5.5

-0.10~0.40

0.45±0.10

0.50±0.10

0.55±0.10

0.60±0.10

100

Φ6.0

-0.10~0.40

0.45±0.10

0.50±0.10

0.55±0.10

0.60±0.10

100

Φ7.0

-0.10~0.50

0.45±0.10

0.50±0.10

0.55±0.10

0.60±0.10

100

Φ8.0

-0.10~0.50

0.45±0.10

0.50±0.10

0.55±0.10

0.65±0.10

50

Φ9.0

-0.10~0.50

0.45±0.10

0.50±0.10

0.55±0.10

0.65±0.10

50

Φ10.0

-0.20~0.70

0.50±0.15

0.55±0.15

0.65±0.15

0.70±0.15

50

Φ11.0

-0.20~0.70

0.50±0.15

0.55±0.15

0.65±0.15

0.70±0.15

50

Φ12.0

-0.20~0.70

0.50±0.15

0.55±0.15

0.65±0.15

0.70±0.15

50

Φ13.0

-0.30~0.80

0.55±0.15

0.60±0.15

0.70±0.15

0.75±0.15

50

Φ14.0

-0.30~0.80

0.55±0.15

0.60±0.15

0.70±0.15

0.75±0.15

50

Φ15.0

-0.30~0.80

0.55±0.15

0.60±0.15

0.70±0.15

0.75±0.15

50

Φ16.0

-0.30~0.80

0.55±0.15

0.60±0.15

0.70±0.15

0.75±0.15

50

Φ17.0

-0.50~1.00

0.60±0.20

0.60±0.20

0.75±0.20

0.80±0.20

30

Φ18.0

-0.50~1.00

0.60±0.20

0.65±0.20

0.75±0.20

0.80±0.20

30

Φ19.0

-0.50~1.00

0.60±0.20

0.65±0.20

0.80±0.20

0.85±0.20

30

Φ20.0

-0.50~1.00

0.60±0.20

0.65±0.20

0.80±0.20

0.85±0.20

30

Φ22.0

-0.50~1.00

0.65±0.20

0.75±0.20

0.85±0.20

0.90±0.20

30

Φ25.0

-0.50~1.00

0.75±0.20

0.85±0.20

0.95±0.20

1.05±0.20

30

Note: Non-standard dimensions and packages also available on your request.