Military Grade Highly Flame Retardant Adhesive-lined Heat Shrink Tubing

- Detailed

Military Grade Highly Flame Retardant Adhesive-lined Heat Shrink Tubing

Description

SBRS-135G (3X)(4X)GFisacross-linked polyolefin tube that is extruded with an inner layer of adhesive.The inner layer of adhesive, with superior sealing capability, is also a bufferagainst mechanical strain. Dual wall heat shrink tubing is designed to providesuperior sealing against water, corrosive gas and chemicals. Typicalapplications include environmental sealing of in-line splices, sealing andstrain relief of connectors and terminals, abrasion protection and electricalinsulation of automotive wiring harness splices and valuable components, fleet& marine sealing & protection and wire bundling etc.

Features

● Standard: AMS-DTL-23053/4 UL 224

● Shrink ratio:3:1,4:1

● High flame retardance,environment friendly,UV resistant

● Shrink temperature:70℃~125℃

● Continuous operating temperature:-45℃~135℃

● RoHS compliant

● Standard color: black outside,white inside

Technical performance

Property

Typical Data

Test Method/Condition

Tensile Strength

≥12MPa

ASTM D 2671

Elongation at break

≥300%

ASTM D 2671

Tensile strength after heat aging

≧ 8.4MPa

175℃×168h

Elongation after heat aging

≥100%

175℃×168h

Longitudinal change

-8%~+8%

ASTM D 2671

Flammability

Self extinguishing in 30 sec.

AMS-DTL-23053/4

Heat Shock

No breakdown,no dripping

UL 224,250℃×4h

Dielectric strength

Flammability

≥15kV/mm

AMS-DTL-23053/4

Flammability

IEC 60243

AMS-DTL-23053/4

Volume resistivity

≥1014Ω.cm

IEC 60093

Technical performance of adhesive

Property

Typical

data

Test

method/condition

Softening point

95±5℃

ASTM E 28

Water absorption

<0.5%

ASTM D 570

Peel strength(PE)

≥120N/25mm

ASTM D 1000

Peel strength(AI)

≥80N/25mm

ASTM D 1000

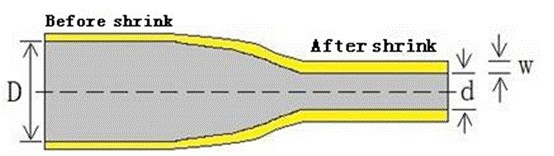

Structure

Dimensions (3:1)

Size

As

supplied D(mm)

After

full recovery(mm)

Standard

package

mm

inch

ID

Wall thickness

Thickness of adhesive

(m/spool,

m/pc)

Φ3.2

1/8

≥3.2

≤1.00

0.90±0.15

0.35±0.10

200

Φ4.8

3/16

≥4.8

≤1.60

1.00±0.15

0.40±0.10

100

Φ6.4

1/4

≥6.4

≤2.20

1.25±0.15

0.45±0.12

100

Φ7.9

5/16

≥7.9

≤2.70

1.30±0.15

0.50±0.12

100

Φ9.5

3/8

≥9.5

≤3.20

1.40±0.15

0.50±0.12

50

Φ12.7

1/2

≥12.7

≤4.20

1.70±0.15

0.50±0.12

25

Φ15.0

5/8

≥15.0

≤5.20

1.80±0.15

0.55±0.15

25

Φ19.1

3/4

≥19.1

≤6.30

1.95±0.15

0.55±0.15

25

Φ25.4

1

≥25.4

≤8.50

2.05±0.20

0.55±0.15

25

Φ30.0

1-1/4

≥30.0

≤10.20

2.20±0.20

0.60±0.15

1.22

Φ39.0

1-1/2

≥39.0

≤13.50

2.50±0.20

0.60±0.15

1.22

Φ50.0

2

≥50.0

≤17.00

2.80±0.25

0.70±0.15

1.22

Dimensions (4:1)

Size

As

supplied D(mm)

After

full recovery(mm)

Standard

package

mm

inch

ID

Wall thickness

Thickness of adhesive

(m/spool,

m/pc)

Φ4.0

2/13

≥4.0

≤1.0

1.05±0.30

0.50±0.20

200

Φ6.0

1/4

≥6.0

≤1.5

1.15±0.30

0.50±0.20

100

Φ8.0

5/16

≥8.0

≤2.0

1.55±0.30

0.60±0.25

100

Φ12.0

1/2

≥12.0

≤3.0

1.75±0.30

0.60±0.25

25

Φ16.0

5/8

≥16.0

≤4.0

2.00±0.35

0.70±0.30

25

Φ20.0

4/5

≥20.0

≤5.0

2.30±0.40

0.70±0.30

25

Φ24.0

1

≥24.0

≤6.0

2.60±0.40

0.75±0.30

25

Φ32.0

1-1/4

≥32.0

≤8.0

3.00±0.50

0.90±0.30

1.22

Φ52.0

2

≥52.0

≤13.0

3.35±0.50

0.95±0.30

1.22