Cold Shrink Coax Connector Sealing Kits

- RUBLS-SILIC

- Excellent weather resistance, ultraviolet aging resistance and higher embrittlement resistance than heat shrink tubing

- More resistant to slab and prick, abrasion, acid and alkali than silicone cold shrink tubing

- Simultaneously expands and shrinks with work pieces without clearances, seals tight in harsh environment

- Stably sealing the work pieces in windy environment

- Well suited for cable less than 1KV

- Seals tight, retains its resiliency and pressure even after prolonged years of ageing and exposure.

- Simple , safe installation, requires no tools or special training. No torches or heat work required.

- Sealing class IP67

- Detailed

VL-KC Cold Shrink Coax Connector Sealing Kits

Description

Features

● Excellent weather resistance, ultraviolet aging resistance and higher embrittlement resistance than heat shrink tubing

● More resistant to slab and prick, abrasion, acid and alkali than silicone cold shrink tubing

● Simultaneously expands and shrinks with work pieces without clearances, seals tight in harsh environment

● Stably sealing the work pieces in windy environment

● Well suited for cable less than 1KV

● Seals tight, retains its resiliency and pressure even after prolonged years of ageing and exposure.

● Simple , safe installation, requires no tools or special training. No torches or heat work required.

● Sealing class IP67

Applications

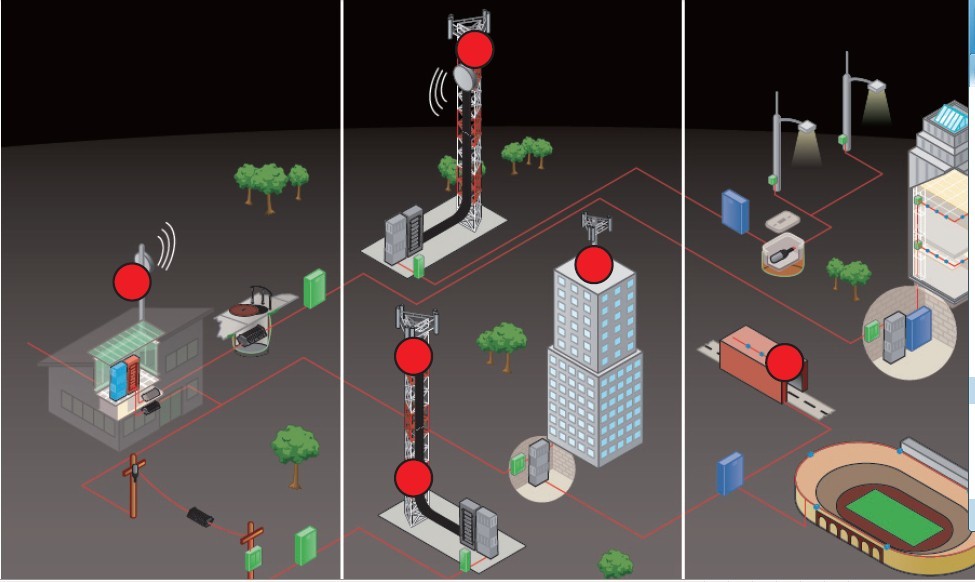

The main application is the sealing of coax connectors used in the wireless communication antenna market. These mainly outside installed connectors require an extra sealing.

Up until now, sealing tapes or Heat Shrink tubes were used.

Technical Information

The outer Cold Shrink tube is made from UV resistant EPDM or Silicone rubber material to provide an excellent seal on the connector. In cases where the different coax cable diameter can not be covered with the tube application range, a special foam is used to increase the smallest cable diameter to fit the shrink performance of the Cold Shrink tube. The kits passed the .5 bares water pressure sealing test and met IEC 529 IP 67.

Technical Date

|

Properties |

Typical Data |

Test method |

|

HS |

49 A |

ASTM D 2240 |

|

Tensile Strength |

11.8 MPa |

ASTM D 2671 |

|

Elongation at break |

641% |

ASTM D 2671 |

|

Tear Strength |

38.6 N/ mm |

ASTM D 624 |

|

Dielectric Strength |

19.1 kV/mm |

IEC60243 |

|

Dielectric Constants |

5 |

90℃(in water) 7 days(1940F)5.6 |

Product Line Application

|

3M Spec. |

Volsun Spec. |

Cables to Connect |

|

98-KC11 |

VL-KC11 |

½” termination or ½” to ½” splice |

|

98-KC21 |

VL-KC21 |

½” to 7/8” splice 5/8” to 7/8” splice |

|

98-KC31 |

VL-KC31 |

½” to 1 1/4” or 1 5/8” splice 5/8” to 1 1/4” or 1 5/8” splice |