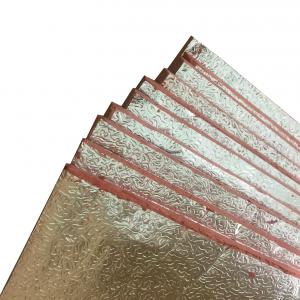

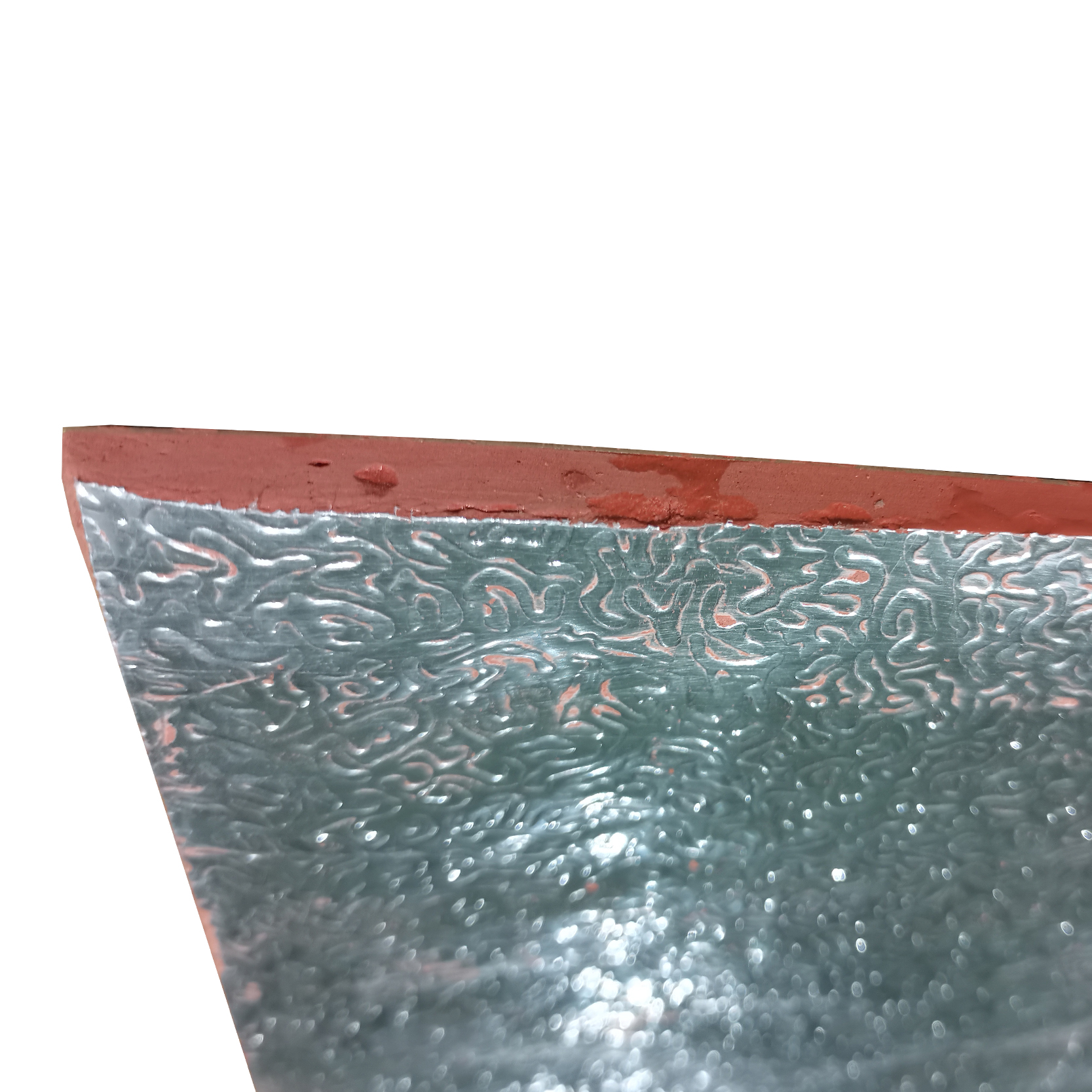

Fire Barrier Composite Sheet

- Detailed

Description

As a new type of composite intumescent fire blocking material, metal composite fireproof sheet can expand to form a carbon layer in case of fire, which helps to slow down the spread of fire, smoke and toxic gases. It is easy to cut, easy to install and construct, can be used for large-area hole sealing and has good bending resistance, fire resistance, smoke blocking, water resistance, oil resistance and corrosion resistance and the fire resistance aging can reach three hours. It is used to block large openings of various penetrations (cables, cable trays, pipes, etc.), and to perform fire-proof sealing of electrical shafts, control cabinets, etc.

Features

l When exposed to fire, it will expand to form a carbon layer, which has good heat insulation and smoke tightness.

l Easy to cut, easy to install and construct

l No contain harmful substances such as asbestos and halogen

l Excellent weather resistance and long service life

Technical Performance

Item

Test Data

Test Standard

Flammability

V0

GB/T 2408-2008

Flexural strength

≥0.10MPa

GB 23864-2009

Water resistance (soaked for 3 days)

≥3d,No swelling, no cracking

GB 23864-2009

Oil resistance (soaked for 3 days)

≥3d,No swelling, no cracking

GB 23864-2009

Fire-resistant level

A3

GB 23864-2009

Moisture and heat resistance

≥120h

GB 23864-2009

Freeze-thaw cycles

≥15times

GB 23864-2009

Dimension

Model

Size(mm)

FST8078

914*914*8

Installation instructions

l Clean the surface of the base layer, cut the FST8078 fireproof sealing board according to the size measured at the opening, and the length of the edge blanking of the board should be greater than 5cm. Place the metal plate toward the outside of the opening and fasten it with bolts.

l Use fireproof mud or fireproof sealant to block the small pores of the board and the blocked object

l Clean the fireproof board and stick warning signs

l Finished

Precautions

l When using a metal composite fireproof sheet, it is necessary to measure the size range of the use environment in advance, and then cut the metal composite fireproof sheet according to the protective size to avoid too large deviation between the size of the metal composite material fireproof sheet and the size of the part to be protected which cannot install or poor protection

l After the installation is completed, the gaps around the metal composite fireproof sheet should be sealed with flexible organic blocking materials or fireproof glue to avoid gaps between the metal composite fireproof sheet and the protected parts, resulting in poor sealing effect.

![]()

![]()

![]()

![]()