The color difference of continous heat shrink busbar sleeving

Time: 2015-05-20 10:48:13 Copyfrom: volsun

When we talk about heat shrink busbar sleeving, we’ll think about the materal they used which is heat shrinkable material.

Heat shrinkable material is based on the plastic linear high polymer or the alloy of high polymer. With high-energy irradiation or chemical methods that make crosslinked polymer molecular chain part mesh structure have elastic memory effect. It can be cooling moulding quickly after heat shrink expansion.when you heating to proper temperature,it will be shrinked to the shape and size before shrink.

Extrude moulding the highly polymer or the alloy of high polymer into givensize will get the tubular intermediate products. After irradiation or chemical cross-linking heat expansion,heat shrink busbar sleeving is produced through cooling moulding process.

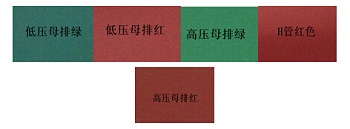

The heat shrink busbar sleeving is the large size heat shrink tube, we always see it have three colors, which is red, yellow and green. But the three colors are not enough on electricity using. The pictures below shows the difference.

From the picture, you’ll see there are color difference on the low voltage and high voltage heat shrink busbar sleeving. Professional tell us there are two reasons of this phenomenon. The first reason is the difference of the high voltage and low voltage heat shrink busbar sleeving material make color difference. The second reason is different batches of raw meterial will bring slightly color difference.