Military Grade, High Temperature, Oil Resistant Identification Tags

- MTVLO

- Resistant to high temperature fuel oil, lubricating oil and other organic solvent

- Side entry Marker tags to big size cables and wire bundles retrofit and repair capability, without broken circuit and run down the machines.

- Easy installation: only standard cable tie-wraps are needed to install marker tags. No extra steps required

- High temperature resistance, rated temp. 135°C

- High flame retardant, VW-1

- ROHS compliant

- Permanent identification, No melting at high temperature, no brittle in low temperature

- Computer-printable, any characters and logo are easy to design.

- Detailed

Military Grade, High Temperature, Oil Resistant Heat Shrinkable Identification Tags

Description

MTVLO-Military Grade, High Temperature, Oil Resistant Marker Tags are made by means of bombardment and cross-linking of the environmentally friendly polyolefin with high energy electron beams. MTVLO boasts amazingly high fluid resistance at high temperature for long time like JP-8 used for aviation fuel oil. Marker tags are non-adhesive that can be used to identify EMU for high-speed rails, subways, submarines and aerospace. Market tags are attached on large cables and wire bundles with cable ties and keep permanent identification.

Features

● Resistant to high temperature fuel oil, lubricating oil and other organic solvent

● Side entry Marker tags to big size cables and wire bundles retrofit and repair capability, without broken circuit and run down the machines.

● Easy installation: only standard cable tie-wraps are needed to install marker tags. No extra steps required

● High temperature resistance, rated temp. 135°C

● High flame retardant, VW-1

● ROHS compliant

● Permanent identification, No melting at high temperature, no brittle in low temperature

● Computer-printable, any characters and logo are easy to design.

Rated Temperature

● Continuous operating temperature: -55°C~135°C/-67°F~275°F

● Max. storage and transportation temp.: ≤50°C/122°F

Standards

● American military standards AMS-DTL-23053/6, NF F 00-608

● Color Code Soundness: SAE-AS 81531and MIL-STD-202F/215J

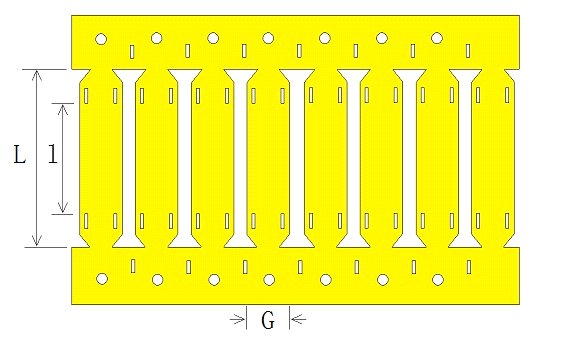

Structure

Technical Performance

|

Performance |

Indicators |

Test Method |

||

|

Typical properties |

Unit |

States |

||

|

Tensile Strength |

Mpa |

Unaged |

≥13.8 |

ASTM G 154, MIL-DTL-23053E ISO 37, 500mm/min 175°C, 168h, ISO188 |

|

Heat aged/ After fluids/UV aged |

≥11.1 |

|||

|

Elongation at break |

% |

Unaged |

≥200 |

|

|

Heat aged/ After fluid |

≥100 |

|||

|

Secant Modulus |

Mpa |

Unaged |

<173 |

ASTM D 882 |

|

Voltage Withstand |

V |

Unaged / After aged |

2500V, No breakdown in 60 sec. |

IEC 243, ASTM G 154 175°C, 168h, ISO 188 |

|

Dielectric Strength |

MV/m |

Before aged |

≥19.7 |

|

|

Heat aged/ After fluid/ UV aged |

≥15.8 |

|||

|

Volume Resistivity |

Ω.cm |

Unaged |

≥1014 |

IEC 93 |

|

Dielectric constant |

- |

Unaged |

≤3.2 |

ASTM 150 |

|

Water Absorption |

- |

Unaged |

≤0.5 |

ASTM 570, 23°C, 24h |

|

Bare Copper Corrosion |

- |

Unaged |

No corrosion |

23°C, Rh 95±5%,24h 175°C,16h |

|

Heat Shock |

- |

Unaged |

No cracks, flowing, dripping |

Wind to the specified mandrel, 225°C, 4h |

|

Cold Flexibility |

- |

Unaged |

No cracks |

Wind to the specified mandrel, -30°C, 1h |

|

Flammability |

- |

Unaged |

VW-1 |

IEC 60332-1-3 Ed.1.0 b:2004 |

|

Smoke Density |

- |

Unaged |

- |

DIN 5510-2 |

|

Toxcity Index |

- |

Unaged |

- |

BS 6853:1999 |

Dimensions

|

Order description |

Width G(mm) |

L Length(mm) |

Printed Characters |

Cable OD(mm) |

|

|

Height G |

Length l |

||||

|

MT-VLO-10.4-45/4- |

10.4 |

45 |

10.4 |

25 |

5.08~12.7 |

|

MT-VLO-10.4-53/4- |

10.4 |

53 |

10.4 |

33 |

5.08~12.7 |

|

MT-VLO-10.4-64/4- |

10.4 |

64 |

10.4 |

44 |

5.08~12.7 |

|

MT-VLO-10.4-76/6- |

10.4 |

76 |

10.4 |

56 |

5.08~12.7 |

|

MT-VLO-10.4-90/6- |

10.4 |

90 |

10.4 |

70 |

5.08~12.7 |

|

MT-VLO-15.0-45/4- |

15.0 |

45 |

15.0 |

25 |

12.7~19.1 |

|

MT-VLO-15.0-53/4- |

15.0 |

53 |

15.0 |

33 |

12.7~19.1 |

|

MT-VLO-15.0-64/4- |

15.0 |

64 |

15.0 |

44 |

12.7~19.1 |

|

MT-VLO-15.0-76/6- |

15.0 |

76 |

15.0 |

56 |

12.7~19.1 |

|

MT-VLO-15.0-90/6- |

15.0 |

90 |

15.0 |

70 |

12.7~19.1 |

|

MT-VLO-20.3-45/4- |

20.3 |

45 |

20.3 |

25 |

19.1~25.4 |

|

MT-VLO-20.3-53/4- |

20.3 |

53 |

20.3 |

33 |

19.1~25.4 |

|

MT-VLO-20.3-64/4- |

20.3 |

64 |

20.3 |

44 |

19.1~25.4 |

|

MT-VLO-20.3-76/6- |

20.3 |

76 |

20.3 |

56 |

19.1~25.4 |

|

MT-VLO-20.3-90/6- |

20.3 |

90 |

20.3 |

70 |

19.1~25.4 |

|

MT-VLO-25.4-45/4- |

25.4 |

45 |

25.4 |

25 |

>25.4 |

|

MT-VLO-25.4-53/4- |

25.4 |

53 |

25.4 |

33 |

>25.4 |

|

MT-VLO-25.4-64/4- |

25.4 |

64 |

25.4 |

44 |

>25.4 |

|

MT-VLO-25.4-76/6- |

25.4 |

76 |

25.4 |

56 |

>25.4 |

|

MT-VLO-25.4-90/6- |

25.4 |

90 |

25.4 |

70 |

>25.4 |