Halogen Free, Low Smoke, Highly Flame Retardant, Identification Tags

- MTVLD

- Halogen free low smoke emitting materials, ideal for identifying motor train unit, rail transit, aerospace and naval vessels

- Not necessary to disconnect the electrical return circuit when installing the identification maker labels

- Using the binding wire, easy to handle

- Temperature resistance, rated temperature 125°C

- Highly flame retardant, low toxicity index, meets international locomotive standards

- RoHS compliant, meets SONY SS-00259

- Permanent identification, not melting in high temp., not turning fragile in low temp., resistant to scrape, rub, abrasion

- Computer-printable, any character and logo are easy to design.

- Detailed

Halogen Free, Low Smoke, Highly Flame Retardant, Heat Shrinkable Identification Tags

Description

MTVLD(DIN) halogen free, low smoke, highly flame retardant marker tags are made by means of bombardment and cross-linking of the environmentally friendly polyolefin with high energy electron beams. Marker tags are non-adhesive that can be used to identify EMU for high-speed rails, subways, motor train units, submarines and aerospace. Market tags are attached on large cables and wire bundles with cable ties and keep permanent identification.

Features

● Halogen free low smoke emitting materials, ideal for identifying motor train unit, rail transit, aerospace and naval vessels

● Not necessary to disconnect the electrical return circuit when installing the identification maker labels

● Using the binding wire, easy to handle

● Temperature resistance, rated temperature 125°C

● Highly flame retardant, low toxicity index, meets international locomotive standards

● RoHS compliant, meets SONY SS-00259

● Permanent identification, not melting in high temp., not turning fragile in low temp., resistant to scrape, rub, abrasion

● Computer-printable, any character and logo are easy to design.

Rated Temperature

● Continuous operating temperature: -55°C~135°C/-67°F~275°F

● Max. storage and transportation temp.: ≤50°C /122°F

Standards

● Material standards: ASTM D 2671/DIN5510-2

● British/French smoke toxicity standards: BS 6853/NF F 16-101

● Color code soundness: SAE-AS 81531 and MIL-STD-202G/215K

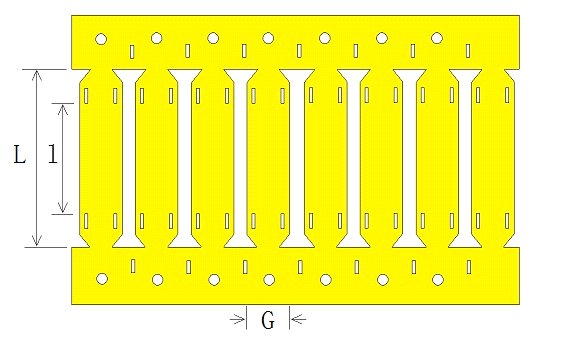

Structure

Technical Performance

|

Performance |

Indicators |

Test Method |

||

|

Typical properties |

Unit |

States |

||

|

Tensile Strength |

Mpa |

Unaged |

≥10.3 |

ASTM G 154,MIL-DTL-23053E |

|

Heat aged/ After fluids/UV aged |

≥6.9 |

|||

|

Elongation at break |

% |

Unaged |

≥200 |

|

|

Heat aged/ After fluid |

≥100 |

|||

|

Secant Modulus |

Mpa |

Unaged |

<173 |

ASTM D 882 |

|

Voltage Withstand |

V |

Unaged / After aged |

2500V,60 seconds without breakdown |

IEC 243,ASTM G 154 |

|

Dielectric Strength |

MV/m |

Before aged |

≥19.7 |

|

|

Heat aged/ After fluid/ UV aged |

≥15.8 |

|||

|

Volume Resistivity |

Ω.cm |

Unaged |

≥1014 |

IEC 93 |

|

Dielectric constant |

- |

Unaged |

- |

ASTM 150 |

|

Water Absorption |

- |

Unaged |

≤1.0 |

ASTM 570,23℃,24h |

|

Bare Copper Corrosion |

- |

Unaged |

No corrosion |

23℃,Rh 95±5%,24h |

|

Heat Shock |

- |

Unaged |

No tracks ,No dripping |

225℃,4h |

|

Cold Flexibility |

- |

Unaged |

No tracks |

-30℃,1h |

|

Flammability |

- |

Unaged |

DIN 5510,S3 |

DIN 5510-2 |

|

Smoke Density |

- |

Unaged |

≤0.017 |

DIN 5510-2 |

|

Toxcity Index |

- |

Unaged |

No tracks ,No dripping |

225℃,4h |

Dimensions

|

Order description |

Width G(mm) |

L Length(mm) |

Printed Characters |

Cable OD(mm) |

|

|

Height G |

Length l |

||||

|

MTVLD-10.4-45/4/ |

10.4 |

45 |

10.4 |

25 |

5.08~12.7 |

|

MTVLD-10.4-53/4/ |

10.4 |

53 |

10.4 |

33 |

5.08~12.7 |

|

MTVLD-10.4-64/4/ |

10.4 |

64 |

10.4 |

44 |

5.08~12.7 |

|

MTVLD-10.4-76/6/ |

10.4 |

76 |

10.4 |

56 |

5.08~12.7 |

|

MTVLD-10.4-90/6/ |

10.4 |

90 |

10.4 |

70 |

5.08~12.7 |

|

MTVLD-15.0-45/4/ |

15.0 |

45 |

15.0 |

25 |

12.7~19.1 |

|

MTVLD-15.0-53/4/ |

15.0 |

53 |

15.0 |

33 |

12.7~19.1 |

|

MTVLD-15.0-64/4/ |

15.0 |

64 |

15.0 |

44 |

12.7~19.1 |

|

MTVLD-15.0-76/6/ |

15.0 |

76 |

15.0 |

56 |

12.7~19.1 |

|

MTVLD-15.0-90/6/ |

15.0 |

90 |

15.0 |

70 |

12.7~19.1 |

|

MTVLD-20.3-45/4/ |

20.3 |

45 |

20.3 |

25 |

19.1~25.4 |

|

MTVLD-20.3-53/4/ |

20.3 |

53 |

20.3 |

33 |

19.1~25.4 |

|

MTVLD-20.3-64/4/ |

20.3 |

64 |

20.3 |

44 |

19.1~25.4 |

|

MTVLD-20.3-76/6/ |

20.3 |

76 |

20.3 |

56 |

19.1~25.4 |

|

MTVLD-20.3-90/6/ |

20.3 |

90 |

20.3 |

70 |

19.1~25.4 |

|

MTVLD-25.4-45/4/ |

25.4 |

45 |

25.4 |

25 |

≥25.4 |

|

MTVLD-25.4-53/4/ |

25.4 |

53 |

25.4 |

33 |

≥25.4 |

|

MTVLD-25.4-64/4/ |

25.4 |

64 |

25.4 |

44 |

≥25.4 |

|

MTVLD-25.4-76/6/ |

25.4 |

76 |

25.4 |

56 |

≥25.4 |

|

MTVLD-25.4-90/6/ |

25.4 |

90 |

25.4 |

70 |

≥25.4 |