Cold Shrink EPDM Rubber Tubing for Coaxial/Coax Cables

- RUBLS-EPDM

- Excellent weather resistance, ultraviolet aging resistance and higher embrittlement resistance than heat shrink tubing

- More resistant to slab and prick, abrasion, acid and alkali than silicone cold shrink tubing

- Simultaneously expands and shrinks with workpieces without clearances, seals tight in harsh environment

- Stably sealing the workpieces in windy environment

- Well suited for cable less than 1KV

- Seals tight, retains its resiliency and pressure even after prolonged years of ageing and exposure.

- Simple , safe installation, requires no tools or special training. No torches or heat work required.

- Diameter shrinkage:≥50%

- Sealing class IP68

- Detailed

RUBLS-EPDM Cold Shrink EPDM Tubes

Connector Insulators RUBLS-EPDM Series

Description

Unique Advantages

● Excellent weather resistance, ultraviolet aging resistance and higher embrittlement resistance than heat shrink tubing

● More resistant to slab and prick, abrasion, acid and alkali than silicone cold shrink tubing

● Simultaneously expands and shrinks with workpieces without clearances, seals tight in harsh environment

● Stably sealing the workpieces in windy environment

● Well suited for cable less than 1KV

● Seals tight, retains its resiliency and pressure even after prolonged years of ageing and exposure.

● Simple , safe installation, requires no tools or special training. No torches or heat work required.

● Diameter shrinkage:≥50%

● Sealing class IP68

Applications

● Primary electrical insulation for all solid dielectric (rubber and plastic) insulated wire and cable splices rated to 1000volts

● Meets ANSI C119.1, directly buriable or submersible

● For indoor, outdoor, or overhead use

● Physical protection and moisture sealing for high-voltage, air-insulated connectors and lugs such as spacer cable and lug connections to bus bar

● Insulation of secondary splices copper or aluminum conductors

● Relocation of service

● Dig-in repairs, sheath repairs

● Insulation of inline conductor transition connectors

● Sealing of coax cables with Type N or 7/16 DIN connectors on wireless communication towers

Technical Performance

|

Properties |

Typical Data |

Test method |

|

HS |

49 A |

ASTM D 2240-75 |

|

Tensile Strength |

9.8 MPa |

ASTM D412-75 |

|

Elongation at break |

720% |

ASTM D412-75 |

|

Tear Strength |

27 N/ mm |

ASTM D624C-73 |

|

Dielectric Strength |

14.3kV/mm |

ASTM 149-75 |

|

Dielectric Constants |

5.0(Initial data)/5.6(90degree in the water for 7 days)) |

/ |

|

Anti-enzyme (bacteria) |

The 28 day exposure without growth |

ASTM G-21 |

|

UV Resistant |

UV irradiation for 2000 hours without aging |

ASTM G-53 |

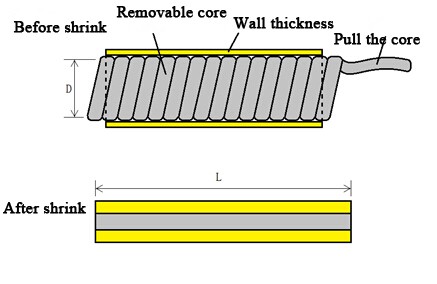

Structure

Dimensions

|

Size (mm) |

Inner Diameter D(mm) |

Min Cable Outer diameter (mm) |

Max Cable Outer Diameter (mm) |

Recovered Length L(mm) |

|

VE18-3 |

Ф18 |

7.8 |

14.3 |

80 |

|

VE18-6 |

Ф18 |

7.8 |

14.3 |

152 |

|

VE18-7 |

Ф18 |

7.8 |

14.3 |

178 |

|

VE24-8 |

Ф20 |

2.54 |

20.9 |

203 |

|

VE25-7 |

Ф25 |

10.1 |

20.9 |

178 |

|

VE25-8 |

Ф25 |

10.1 |

20.9 |

203 |

|

VE25-11 |

Ф25 |

10.1 |

20.9 |

279 |

|

VE25-12 |

Ф25 |

10.1 |

20.9 |

305 |

|

VE28-5 |

Ф28 |

8.0 |

22.5 |

125 |

|

VE35-6 |

Ф35 |

13.9 |

30.1 |

152 |

|

VE35-8 |

Ф35 |

13.9 |

30.1 |

203 |

|

VE35-9 |

Ф35 |

13.9 |

30.1 |

229 |

|

VE35-11 |

Ф35 |

13.9 |

30.1 |

279 |

|

VE42-6 |

Ф42 |

16.8 |

35.1 |

152 |

|

VE42-8 |

Ф42 |

16.8 |

35.1 |

203 |

|

VE42-10 |

Ф42 |

16.8 |

35.1 |

254 |

|

VE42-12 |

Ф42 |

16.8 |

35.1 |

305 |

|

VE42-16 |

Ф42 |

16.8 |

35.1 |

406 |

|

VE42-18 |

Ф42 |

16.8 |

35.1 |

457 |

|

VE50-8 |

Ф50 |

13.5 |

43.7 |

203 |

|

VE58-6 |

Ф58 |

24.0 |

49.3 |

152 |

|

VE58-7 |

Ф58 |

24.0 |

49.3 |

178 |

|

VE58-8 |

Ф58 |

24.0 |

49.3 |

203 |

|

VE58-10 |

Ф58 |

24.0 |

49.3 |

254 |

|

VE58-12 |

Ф58 |

24.0 |

49.3 |

305 |

|

VE58-18 |

Ф58 |

24.0 |

49.3 |

457 |

|

VE58-24 |

Ф58 |

24.0 |

49.3 |

610 |

|

VE58HP-10 |

Ф58 |

20.5 |

51.0 |

254 |

|

VE65-10 |

Ф65 |

23.7 |

57.5 |

254 |

|

VE77-6 |

Ф77 |

32.2 |

67.8 |

152 |

|

VE77-7 |

Ф77 |

32.2 |

67.8 |

178 |

|

VE77-9 |

Ф77 |

32.2 |

67.8 |

229 |

|

VE77-12 |

Ф77 |

32.2 |

67.8 |

305 |

|

VE77-13 |

Ф77 |

32.2 |

67.8 |

330 |

|

VE77-14 |

Ф77 |

32.2 |

67.8 |

355 |

|

VE77-18 |

Ф77 |

32.2 |

67.8 |

457 |

|

VE77-22 |

Ф77 |

32.2 |

67.8 |

550 |

|

VE77HP-13 |

Ф77 |

27.4 |

70.0 |

330 |

|

VE105-8 |

Ф105 |

42.6 |

93.7 |

203 |

|

VE105-9 |

Ф105 |

42.6 |

93.7 |

229 |

|

VE105-18 |

Ф105 |

42.6 |

93.7 |

457 |

|

VE105-20 |

Ф105 |

42.6 |

93.7 |

508 |

|

VE120-24 |

Ф120 |

33.0 |

114.3 |

610 |

|

VE160-24 |

Ф160 |

60.0 |

154.0 |

620 |