Why do we need to make 2nd vulcanization for the cold shrink tube

Time: 2021-10-26 14:36:30 Copyfrom: SuZhou Volsun Electronics Technology Co.,Ltd.

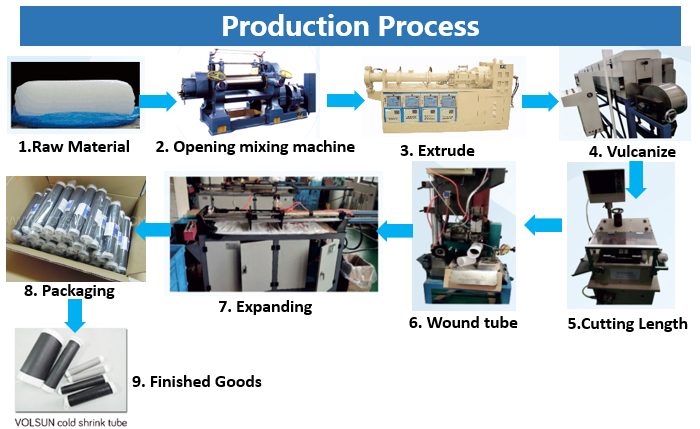

Cold shrink tubing is currently divided into silicone cold shrink tubing and EPDM cold shrink tubing according to the main raw material for manufacturing,which are made of silicone rubber and EPDM.The principle of shrinkage is the same,so the following is an example of silicone cold shrink tube.

More detail about cold shrink tube technology,please contact us by volsuntube@szvolsun.com

KEYWORD:cold shrink tube,silicone cold shrink tube,cold shrink tubing

RELATED_ARTICLES:

Busbar heat shrink tube for transformers and switchgears

White silicone rubber insulation heat shrink tube

Heat Shrink Tube for circuit board protection

Idetification heat shrink tube for electric motor system insulation